According to ASTM F2792-12 (Standard Terminology for Additive Manufacturing Technologies), Additive Manufacturing (AM) can be described as, ‘a process of joining materials to make objects from 3D model data, usually layer upon layer’. AM enables the fabrication of objects through the deposition of material in order to obtain fit-for-purpose hardware, as opposed to traditional subtractive processes, where material is removed from larger, semi-finished products.

Like many new manufacturing processes, 3D printing arose from the merging of previously existing technologies, the coming together of Computer Aided Design (CAD), inkjet nozzles and automated machine systems. AM includes a large family of processes and technologies and can be applied to a wide range of materials ranging from metals, polymers and ceramics but also food, living cells and organs.

Plastic printing arrived first, initially used for rapid prototyping purposes, but metals and ceramics came soon after. The most common processes for metals include Powder Bed Fusion, using a laser or an electron beam, and Direct Metal Deposition, where powder is blown into the molten pool, also by means of a laser. Wire Arc Processes use metal wires instead of powders for additive manufacturing of large structures, and polymers are typically processed via Selective Laser Sintering (SLS), stereo-lithography (also used on ceramics) or Fused Deposition Modelling (FDM).

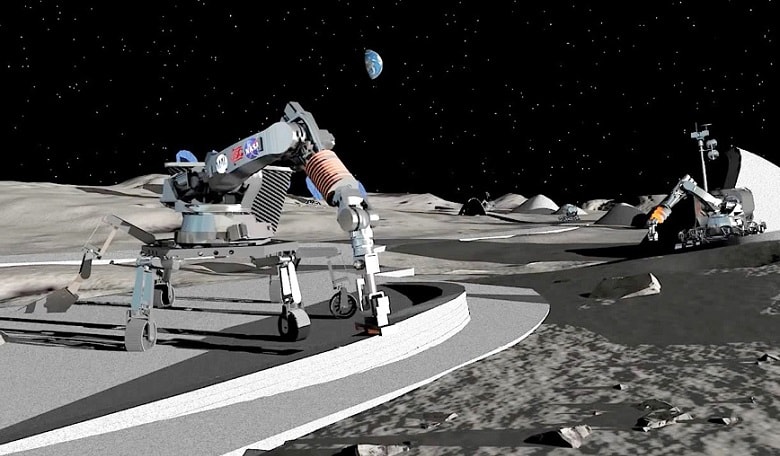

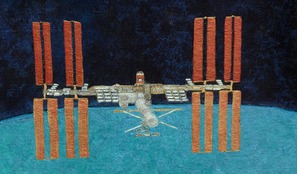

Read more on how new 3D printing technologies can help us build bases on the Moon and be used in other creative ways in space, in the full version of the article, available to our subscribers.