A return to the Moon has become a high priority for many international space agencies and companies wanting to stamp their mark on the dusty lunar surface, either by undertaking scientific experiments or to mine it for potential resources. Some even want to go further and build a Moon village. But how do you go about building a habitat on another celestial body when the cost of transporting materials into space is enormous? One company is offering a solution – 3D print your own infrastructure by melting moon dust with lasers to make it usable as building material.

This ambitious project, called MOONRISE, is being led by the German independent, non-profit research institute the Laser Zentrum Hannover e.V. (LZH) along with the Institute of Space Systems (IRAS) of the Technical University of Braunschweig. It involves a laser system that weighs no more than three kilograms that can melt down local raw materials on the Moon and convert them into versatile structures for later use.

And we’re not talking about a far-off plan that will be ready to go in a couple of decades; the scientists behind the project want to demonstrate the uses of additive manufacturing on the Moon by the end of 2021.

"IRAS and LZH have been working together on the underlying process for the MOONRISE technology since 2015. Now, through the project, we have the opportunity to show Additive Manufacturing outside of the earth and of the earth's orbit for the first time in history," explains Professor Enrico Stoll from the IRAS.

MOONRISE will hitch a ride on the first Moon mission of the Berlin-based new-space company PTScientists, a privately funded organisation who have just signed a cooperation agreement with the ArianeGroup to work together on future Moon missions such as the planned ISRU mission of the European Space Agency (ESA).

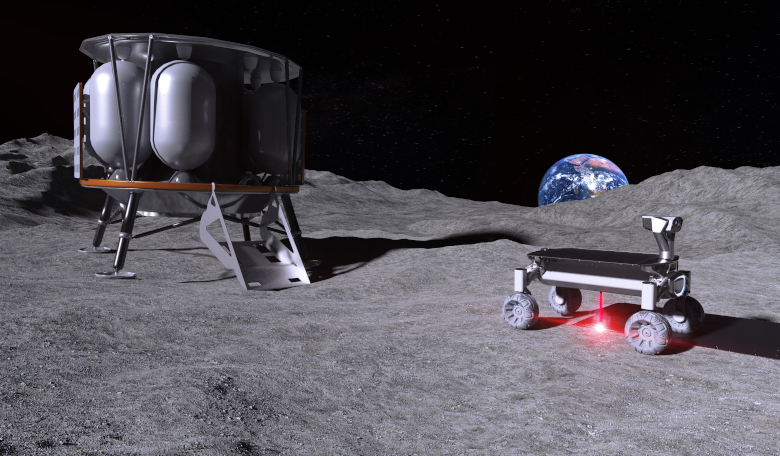

PTScientists are planning to undertake the first fully privately funded mission to land on the Moon with a pair of Audi lunar quattro rovers and whilst there, they plan to capture the first high definition images from NASA’s historic Apollo 17 landing site. Stowed on board the spacecraft alongside the two rovers will be the MOONRISE payload.

The MOONRISE project has been in the testing phase for nearly nine months now and the results so far look promising say the scientists working on the technology. "The time is very short to make the process safe, to set up and test the appropriate laser while keeping the weight budget," says Professor Ludger Overmeyer from the LZH. "But only those who try the impossible have the chance to achieve it."

Currently, the team are working on adapting the laser to fit on the lunar rover, which is integrated into a tunnel at the bottom of the vehicle. After the adjustments, the entire system will then be tested to see if it can survive the rigours of space, including the bumpy ride to the surface and the massive temperature differences it will encounter once it is deployed to the surface.

MOONRISE is being financed by the Volkswagen Foundation, Germany’s largest independent funder of basic research, but even if the in-situ experiment doesn’t quite go according to plan, the backers are confident that the scientific and technical 3D knowledge acquired during the mission will have been worthwhile.

"Fundamentally new insights can often only be gained if scientists and their supporters are willing to take risks," says Dr. Wilhelm Krull, Secretary General of the Volkswagen Foundation. "Even if the outcome of the experiments is still unclear, the foundation wants to resolutely set the path for daring research ideas like this one."