Engineers at the University of Cincinnati are developing a new technique that could suck carbon dioxide out of Mars’ atmosphere so that it could be used as rocket fuel to get astronauts home if humanity ever sets foot on the Red Planet.

The process, which uses a carbon catalyst in a reactor to convert carbon dioxide into methane, is known as the "Sabatier reaction" after the late French chemist Paul Sabatier who discovered the reaction with Jean-Baptiste Senderens in 1902.

This means of producing synthetic natural gas via methanation reactions of CO2 has not gone unnoticed and is used in space right now to help astronauts aboard the International Space Station.

On the ISS, carbon dioxide is removed from air so that its inhabitants can breathe, and like the situation envisaged for Mars, the converted gas is also used to generate rocket fuel to keep the station in high orbit.

Despite the obvious differences, the principle behind the process should be the same says UC College of Engineering and Applied Science assistant professor Jingjie Wu

"It's like a gas station on Mars. You could easily pump carbon dioxide through this reactor and produce methane for a rocket," he says.

Mars might have a thin, tenuous atmosphere compared with Earth’s, but the wispy skies it does have is composed of 95 percent carbon dioxide, 3 percent nitrogen, 1.6 percent argon, along with traces of other gases and lots of dust.

Wu suggests that potential martian astronauts could save half the fuel they need for a return trip home by making what they need on the red planet once they arrive.

"Right now if you want to come back from Mars, you would need to bring twice as much fuel, which is very heavy," Wu says. "And in the future, you'll need other fuels. So we can produce methanol from carbon dioxide and use them to produce other downstream materials. Then maybe one day we could live on Mars."

But the idea of converting CO2 to another gas is more versatile than just the production of rocket fuel says Wu.

Right now our planet is experiencing rising average temperatures due to an excess of carbon dioxide.

Released into the skies by the burning of coal, natural gas and oil, CO2 absorbs and emits infrared radiation from the Sun and acts like a blanket in the air, trapping heat in the atmosphere.

Reports suggest that global CO2 emissions from human activity have increased by over 400 percent since 1950.

This increase is having a knock-on effect with Earth's climate by causing changes in weather patterns, food supply disruptions, and increased wildfires to name just a few worrying effects.

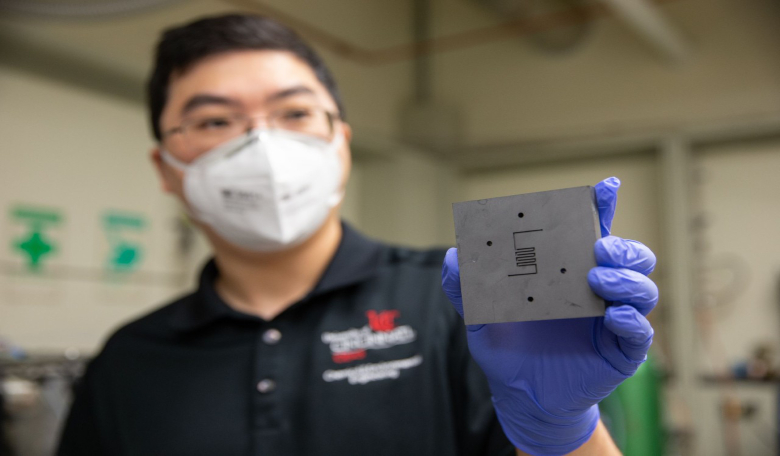

Wu and colleagues CO2 reactor could eventually help reduce this potent greenhouse gas. Currently under development, the team are experimenting with different catalysts such as graphene quantum dots - layers of carbon just nanometers big - that can increase the yield of methane.

This style of metal-free electrocatalysts benefit from having a large effective surface area for the reactions to take place, are low cost and have enhanced mechanical resilience compared with the metal variety.

As well as helping to mitigate climate change, CO2 could be recycled into ethylene. Called the world's most important chemical, ethylene is used in the manufacture of plastics, rubber, synthetic clothing and other products.

The conversion of CO2 could also be used to store renewable energy. "Right now we have excess green energy that we just throw away. We can store this excess renewable energy in chemicals," Wu said.

Perhaps one of the biggest advantages of such a system is that the process is scalable. That means it could be used directly for use in power plants, one of the main sources for the production of CO2.

"The process is 100 times more productive than it was just 10 years ago. So you can imagine that progress will come faster and faster," Wu said. "In the next 10 years, we'll have a lot of startup companies to commercialise this technique."