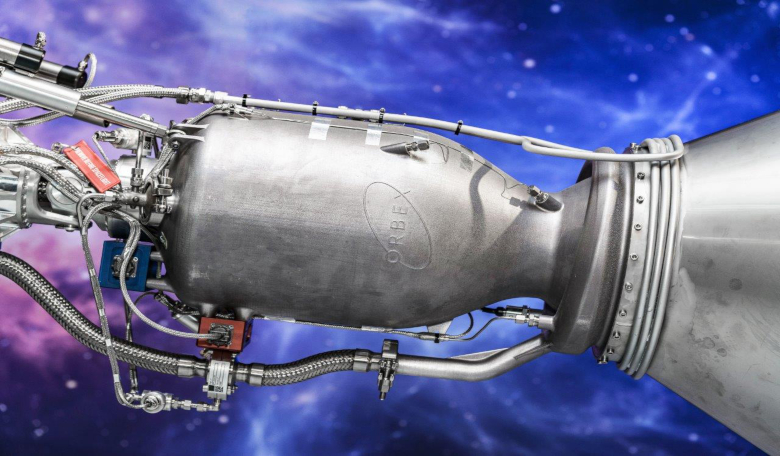

Spaceflight company Orbex has commissioned AMCM in Germany to build the largest industrial 3D printer in Europe, giving the innovative UK-based space launch business the capability to rapidly print complex rocket engines in-house.

The custom-made, large volume 3D printer will allow Orbex to print more than 35 large-scale rocket engines and main stage turbopump systems annually, as the company scales up its production capabilities for launches of its Prime rocket.

The multi-million pound deal was signed with AMCM after a series of successful trials printing various large-scale rocket components over a number of months. AMCM will deliver a complete printing suite with post-processing machinery and 'Machine Vision' systems, providing automatic imaging-based inspection of printed components. To accommodate the new machinery, Orbex is expanding its factory floor space by an additional 1,000 square metres.

The 3D printing system will print rocket parts using a custom blend of metals including titanium and aluminium to create a lightweight system designed to withstand the temperature and pressure extremes of spaceflight. Orbex will print components such as rocket engines as a single piece, eliminating the weaknesses which can arise from joining and welding.

The 3D printed rocket components will be critical parts of Orbex's launch vehicle, a 19 m long ‘microlauncher’ rocket, designed to deliver small satellites into polar orbits around the Earth. Planning permission was granted for Orbex's home spaceport, Space Hub Sutherland, at the A'Mhoine peninsula in Sutherland in August 2020. The A'Mhoine site is currently the only UK spaceport to receive planning permission, with construction expected to begin during 2021 and the first orbital launch expected in 2022.

Uniquely for a commercial rocket, Prime is fuelled by bio-propane, a clean-burning, renewable fuel which reduces CO2 emissions by 90 percent compared to kerosene-based fuels. The Prime rocket was designed to be re-usable, incorporating a novel recovery and reusability system. The rocket has also been designed to leave zero debris in orbit around the Earth.

"Although our rocket engines and other critical systems are already quite mature after years of testing, a large-scale in-house 3D printing system like this gives us far greater speed and agility as we ramp up production," said Chris Larmour, CEO of Orbex.

"It means we can continue to iterate and drive up performance even further. Longer term, as we get ready for multiple launches per year, it will give us greater control over our costs and supply chain. After exhaustive trials, the results we've seen from AMCM were very successful and we're confident that we've made the right choice of partner."

"Investing in a large-scale 3D printing system like this says a lot about Orbex's ambition in the European spaceflight sector," said Martin Bullemer, managing director of AMCM. "If they are to lead the European market, they need the production reliability and speed that a large-scale 3D printing system like this will give them. And although this is a major purchase, it will allow for significant cost control for Orbex in the years to come."

Orbex recently announced that it had secured $24 million in a funding round led by BGF, the UK's most active investment company, and Octopus Ventures, one of the largest VCs in Europe. The additional funding brings significant new investment in high technology employment opportunities and large-scale production facilities in the Highlands region of Scotland.