With a launch success rate of 97 per cent, the H-IIA rocket has been blazing a trail for reliability. But the Japanese space industry is not resting on its laurels. An upgraded H-IIA that’s powerful enough to change a satellite’s orbital plane, thereby extending its working lifespan, will be available this year. On the horizon is a successor capable of launching the heaviest payloads into orbit and a radical, reusable launcher.

The H-IIA rocket developed by NASDA (Japan’s National Space Development Agency) has been Japan’s flagship rocket since its first flight in 2001. In 2007, the launch business for the H-IIA was transferred from JAXA (Japan Aerospace Exploration Agency, Japan’s successor to NASDA) to Mitsubishi Heavy Industries. The rocket completed its 28th launch in 2015.

The most important characteristic of a launch vehicle is reliability: in other words, the launch success rate. The H-IIA has a launch success rate of 97 per cent, the highest ever achieved. More impressive still, about 70 per cent of the flights have been “on-time launches”, launched from the ground as originally planned without delays.

The orbit insertion accuracy is a key determinant of the service life of a satellite launched on a rocket. The H-IIA insertion accuracy generally falls within 1-sigma, which is one-third of the permissible variation agreed with the satellite operator prior to flight.

The launch site for the H-IIA rocket, the Tanegashima Space Center, is widely regarded as the world’s most beautiful launch site by dint of its superb views of blue sea, white sandy beaches, and green hills. However, this picturesque location has a disadvantage compared to launch sites further south.

A spacecraft circles the Earth in an elliptical orbit, with one focus on the centre of the Earth. A launch vehicle flies in basically the same way. After lift-off, the vehicle performs geocentric and in-plane motions to guide itself to the satellite injection point. Most commercial satellites operate in geostationary orbit - a circular orbit 36,000km above the equatorial plane. For this reason, the simplest launch is to lift off from the equator into an orbit with an apogee of 36,000km and a perigee of several hundred km. A satellite generally separates from its rocket before reaching its apogee but retains enough kinetic energy to complete the journey.

After an inertial flight of several hours, the satellite reaches its apogee and accelerates to a speed of about 1500m/s with a propulsion device. Once this speed is established, the satellite attains a geostationary circular orbit.

Tanegashima Space Center, and therefore the H-IIA rocket, is therefore at a geographical disadvantage because its latitude is 30 degrees north. The H-IIA places the satellite in a plane forming a 30-degree angle (inclination) relative to the equator. When ascending to its apogee, a satellite launched by the H-IIA must switch from an orbital plane to an equatorial plane.

To achieve this, it must accelerate to a speed of 1800m/s, or 300m/s faster than the speed required after the simplest equatorial launch. The satellite burns more fuel to attain this extra 300m/s in speed, which shortens its service life by several years after reaching geostationary orbit. At present, the service life of a typical satellite is only around 15 years. Given its short life to begin with, the fuel consumed for a change in orbital plane is a considerable drawback for satellite operators.

However, a new upgrade to the H-IIA technology now enables the rocket to perform the plane change instead of the satellite. This reduces the fuel burden to the same as that of a satellite launched from the equator.

The H3: right for the market

The upgraded H-IIA is scheduled to launch a Telesat Telstar 12V satellite in autumn of 2015. It will employ a five-hour coast to the apogee neighbourhood and a third combustion by the second stage engine for orbit plane changes. The launcher runs on liquid hydrogen and liquid oxygen fuel, the highest-performance propellants. Liquid hydrogen and liquid oxygen are both cryogenic, which requires a key enabling technology to suppress fuel evaporation during the five-hour coast.

The H-IIA upgrade adopts a white, heat-insulating paint on the second stage, introducing a ‘thermal roll’ to avoid local heating by solar input during the coast. To minimize fuel consumption for engine chill-down before the third combustion, a trickle precooling system is attached to the second stage engine. Trickle precooling minimizes the intermittent flow of liquid oxygen into the turbo pump, which keeps the pump temperature cool enough for the third engine start.

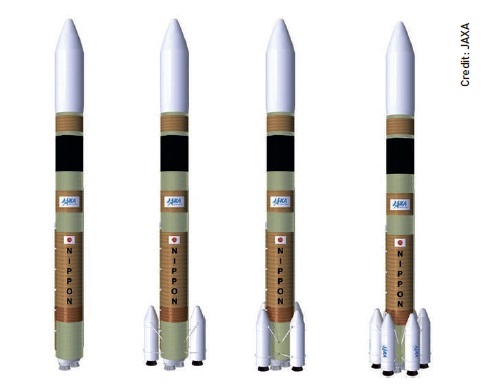

Upgrading the H-IIA is just the start, however. Japan has plans for a new rocket, the H3, that will serve the international launch market. Incorporated into Japan’s basic space plan, the H3 will enhance the country’s autonomous space access and strengthen its global competitiveness. By design, the H3 rocket will meet the launch demand of Japanese institutions and capture a reasonable share of the highly competitive international launch market in the 2020s.

The development and testing of reusable rocket technology is a key focus for Japan’s space industry

The development and testing of reusable rocket technology is a key focus for Japan’s space industry

According to market forecasts up to around 2035, satellite mass is moving in two opposite directions: lighter and heavier. This demand trend mainly stems from the widespread use of electric propulsion systems. Under current plans, the H3 rocket will accommodate demand by launching a broad band of satellite masses. Three vehicle configurations will carry satellites weighing from 2.5 tons to 7 tons into geostationary orbit.

The H-IIA has a launch success rate of 97 per cent, the highest ever achieved

Technologies that are both low cost and provide high system reliability will be key to achieving the H3 development objectives. Technologies so far planned include a more robust combustion cycle for the 1st stage engine, manufacturing with 3D printing, and commercial off-the-shelf parts in place of custom-made parts for space use.

The H-IIA 1st stage main engine adopts a two-stage combustion cycle that performs at world-class levels by utilizing propellant more efficiently. This comes with tradeoffs, however, as the technology requires a complex engine system and a growing number of parts for the multiple combustion chambers. The engine start sequence requires exact timing control in fuel valve operations. Unlike the LE-7A, the main engine for the H3, the LE-9, uses the same expander breed cycle applied to the H-IIA 2nd stage engine. This expander breed cycle has only one main combustion chamber, which reduces the number of parts and has a simple engine structure. The LE-9 exhausts the hydrogen gas after it powers the turbo-pump, instead of using the gas for combustion. The engine start sequence is therefore simpler than a two-stage combustion cycle, as well as giving a robust response to variations in the oxygen/hydrogen mixture ratio.

The upgraded H-IIA rocket undergoes thermal vacuum testing ahead of its launch in autumn 2015

The upgraded H-IIA rocket undergoes thermal vacuum testing ahead of its launch in autumn 2015

Aerospace manufacturers use 3D printing technology to build up three-dimensional structures by selectively melting and solidifying metal powders. The process is free from metallic moulds and configures complicated shapes very close to specification for final products at a sharply reduced manufacturing cost. The engine valve of the LE-9 is an example of a component fabricated by 3D printing.

Reusable transportation

Electronic components of the launch vehicle were specifically designed, produced and verified to withstand mechanical stresses such as vibration and shock during flight. The small number of components produced drastically raises the cost of manufacturing electric components on a per-unit basis.

The Tanegashima Space Center is widely regarded as the world’s most beautiful launch site

Thanks to the recent evolution of electronic components applied to aircraft and automobiles, some types of mass-produced parts are tough enough to withstand the harsh environment of launch vehicle flight. These parts are less expensive than space-specific parts and reach high levels of quality through mass production. Civil components such as these can be incorporated into the H3 to drive down cost with no compromise in reliability.

Concepts for the H3 rocket, capable of launching satellites large and small for industries worldwide

Concepts for the H3 rocket, capable of launching satellites large and small for industries worldwide

The single-use H3 isn’t the only project on the drawing board, however. A reusable rocket is planned, building on advances made in the past few decades. In the 1970s, the Space Shuttle developers considered the repeat use of a vehicle to reduce the cost of transportation. The orbiter and solid rocket booster motor case were both reused. Later, when the Shuttle was used for practical missions, the burdens of inspection and repair after every flight proved far heavier than expected. The recurring cost hikes of the operation were an unpleasant surprise.

In the near future, space transportation systems are expected to become fully reusable through the application of advanced technologies and stringent requirements for easy access to space. Japan is engaged in practical research to generate a reusable sounding rocket as a precursor to a fully reusable launch system. Key goals for this research are to establish a process for the design, manufacture and verification of reusable hardware for launch vehicles and to define and verify the operational processes, from vehicle retrieval to re-flight. Key outputs will include not only elemental technologies, but an actual flying system for practical use.

The reusable sounding rocket will replace the current expendable rocket. It will be used to conduct micro-gravity tests and collect high-altitude atmospheric data for scientific analysis at a much lower operational cost.

Surrounded by sea, sand and green hills, Japan’s Tanegashima Space Center has a disadvantage compared to facilities nearer the equator

Surrounded by sea, sand and green hills, Japan’s Tanegashima Space Center has a disadvantage compared to facilities nearer the equator

A series of engine firing tests on the 40kN reusable liquid hydrogen/oxygen engine have been completed, which brings this research to the end of the fundamental technology demonstration phase. Engine throttling was tested to verify the smooth thrust change required to support safe retrieval of the vehicle. Further research on reusable operation will culminate in a full-scale, fully reusable space transportation system in the near future.

Japan’s effort to prepare a space transportation system began in the 1970s. Ongoing research and practical endeavours have since raised Japan’s performance in aerospace to an unprecedented level internationally. The technologies developed are poised for deployment to customers all over the world. Japan will spare no effort to upgrade both the reliability and the user-friendliness of its space transportation systems in the years to come.