The Self-Deployable Habitat for Extreme Environments (SHEE) is a test bed for terrestrial simulations of space missions. Available in 2016 to interested parties conducting mission simulations in analogue sites, it’s ideal for conducting scientific research on the effects of confinement and for testing space-related systems and technologies.

SHEE is the result of a three-year project developed under the European Commission between January 2013 and December 2015. The first deployable habitat simulator to be designed and constructed in Europe, SHEE was developed by a consortium of seven partners led by the International Space University. The consortium included two space architecture companies: Liquifer Systems Group of Austria and Space Innovations of Czech Republic.

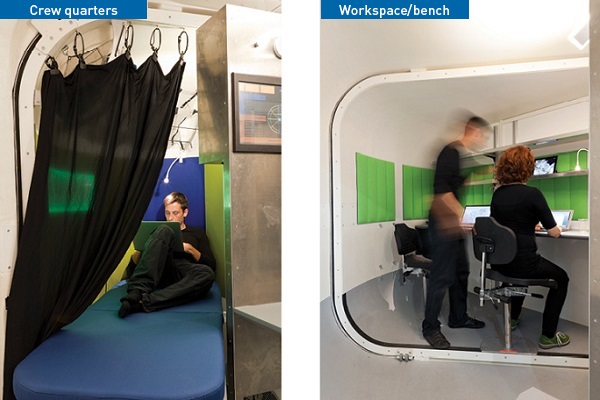

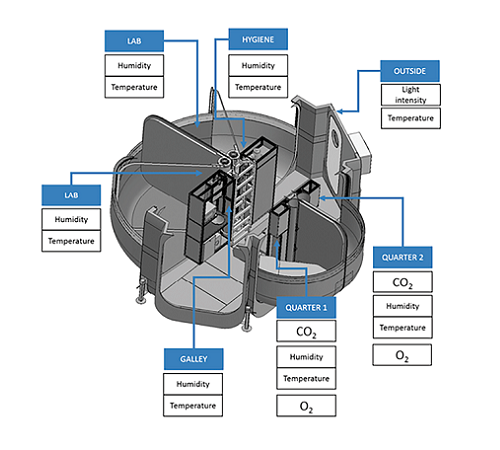

Distinctive features of SHEE include its easy transportability – it’s the size of a standard Euro shipping container - and its capacity to automatically deploy, increasing the size of the habitat and usable space to accommodate a two person-crew. The overall inhabitable volume of approximately 50m? was based on current NASA/ESA studies suggesting 20-25m? per person. It’s outfitted with interior furnishings that permit different usage and activity, including sleeping cabins, a work area, a multi-functional common area, a hygiene compartment and a small workshop.

The habitat’s Environmental Control and Life Support System (ECLSS) can sustain a twoperson crew for two weeks

The Environmental Control and Life Support System (ECLSS) can sustain a two-person crew for two weeks. It is anticipated that elements of the SHEE design will have practical applications in any hostile environment requiring human presence, on or off the Earth.

Initially, different concepts for the design and configuration of the habitat were devised and trade-off criteria were weighted. Priorities that rated highest were deployment simplicity, structural simplicity, deployed/stowed ratio and structural robustness. Based on these parameters, a design concept was chosen that would be fully developed during the course of the project.

The structure

Structurally, the design of SHEE is a load-bearing monohull structure with six deployable compartments (referred to as petals). The manufacturing method, as well as the materials, used to construct the structural components are similar to those used in the boating and yachting industries for composite hulls. Stiffness and strength criteria were verified for both stowed and deployed configurations using safety factors and recommendations from Industrial standards NASA-GSFC-STD-7000A-1 and MIL-STD-810F. Structural verification performed by means of Finite Element Analysis (FEA) using PTC Creo Simulate software informed the preliminary design and validated design hypotheses along the way. Analysis of the structure took into account different load cases, for a range of different scenarios. The final structural verification of SHEE showed a positive margin of safety for all cases analysed.

The SHEE habitat in its deployed configuration … and its folded configuration

The SHEE habitat in its deployed configuration … and its folded configuration

The self-supporting structure of the main hull is made of stiffened, 60mm-thick, sandwich panels of fibreglass with a core of foam material. The main hull was manufactured in two halves, which attach to one another by means of an equatorial metallic flange. The petals were manufactured using the same principle as the main hull with a thickness of 30mm. Exterior surfaces of all components have a fireproof gel coat, and the core material is a thermo-plastic honeycomb filled with closed cell thermoplastic foam. The benefits of the core material are two-fold: inhibiting rip propagation, like honeycombs; and providing superior heat and noise insulation, like foam cores.

The deployment of the habitat, also called ‘actuation’, consists of rotary motions that are driven from a central axis. The system was selected mainly because of the availability of tried-and-tested, off-the-shelf components. The drives are compact and are located in the floor and ceiling compartments.

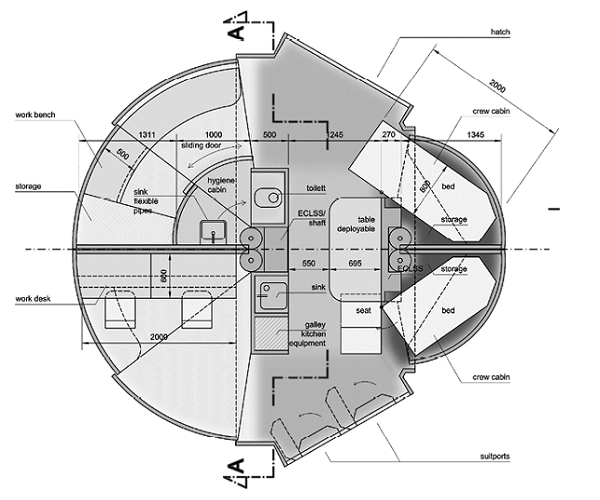

SHEE Consortium, photo: Bruno Stubenrauch, 2015

SHEE Consortium, photo: Bruno Stubenrauch, 2015

SHEE Consortium, photo: Bruno Stubenrauch, 2015

SHEE Consortium, photo: Bruno Stubenrauch, 2015

SHEE Consortium, photo: Bruno Stubenrauch, 2015

SHEE Consortium, photo: Bruno Stubenrauch, 2015

In total, six petals automatically deploy from within the main body of the habitat. They are divided equally into two groups and are symmetrically aligned on the central axis within the stowed habitat. Deployment of the petals is synchronised, so that identically dimensioned petals on either side of the axis are paired together during actuation. Each petal in the set has an individual gearbox, but the same motor drives the set. The actuation is done by 800W electric motors running on 24V DC, and the position of the petals is tracked using a rotary encoder located directly on the pivot axis.

Life support systems

Inflatable seals fill the gaps between the moving petals and the main hull. The seals are fully inflated after the habitat is deployed but must be deflated using a vacuum pump during their motion. In case of total power failure, the habitat can also be opened and closed manually with the aid of external batteries or other power sources.

Total autonomy for humans in space is a long-term goal, and has not yet been completely achieved by the industry as a whole, but the Environmental Control and Life Support System (ECLSS) of SHEE is successful in recycling water and regenerating consumed air.

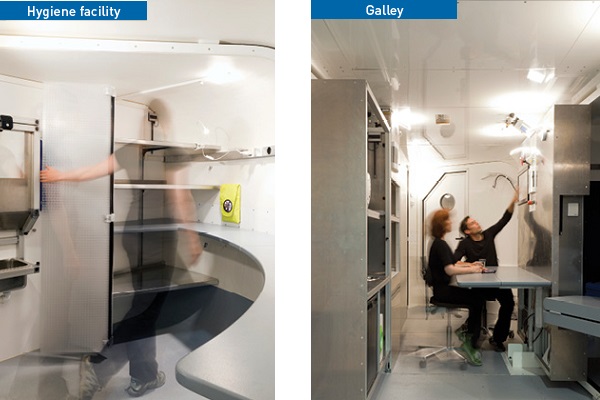

ECLSS components are provided in the form of modular racks, which can be replaced by other functional elements if needed. The kitchen rack of SHEE includes items that enable the astronauts to prepare and store food, such as a microwave oven and refrigerator, and a dehydration unit to reduce the food’s size and recover water from it. A hygiene rack includes a toilet (gravity based) and a sink for personal hygiene. The ‘monitoring and ventilation rack’ is comprised of two small racks and includes the environmental monitoring system, the air conditioning and two ventilation units.

The final baseline concept for the SHEE habitat

The final baseline concept for the SHEE habitat

SHEE life support systems location and measurements

SHEE life support systems location and measurements

In addition to the rack components, the interior furnishings are modular and can be modified depending on the specific needs of a mission. Internal furnishings can be fastened to the rigid exterior structural shell at hard contact points by means of insertion and threading. In addition, a ‘virtual window’ was integrated to change the colour of light within the habitat.

Elements of the SHEE design will have practical applications in any hostile environment requiring human presence, on or off the Earth

To fully explain the SHEE design and its complexity, a researcher’s user manual will be provided to guide science preparation and planning prior to utilization. In preparation for the first mission, the SHEE habitat is being tested in a laboratory environment. Tests include: exterior operations including repeated deployment and stowing; interior operations; and logistics and set-up requirements. These tests include functional testing of the designed, built and integrated systems, and user-based testing of the experience and operations.

In use, the SHEE concept will be flexible enough to fulfil a variety of possible roles in a number of environments. Indeed, the architecture allows several habitats to be combined. A ‘SHEE village’ could include modules that serve as living bases, with laboratories, greenhouses or medical stations.

Advances in technology and configuration incorporated in the SHEE habitat provide significant background for further development and evolution of extra-terrestrial habitable structures. What’s more, the folding capability of the habitat will allow interdisciplinary research and tests of various technologies in different analogues in Europe and worldwide.