Canada-based Space Engine Systems, which is developing a two-stage horizontal launch and landing vehicle, has been raising its profile recently at major international conferences and exhibitions, including IAC 2023 in Baku, Azerbaijan. The company also enjoyed a high-profile presence in the Space Zone at the 2024 Farnborough International Airshow where ROOM Editor Mark Williamson spoke to Pradeep Dass, President & CTO.

One of the holy grails of astronautics is the single stage to orbit (SSTO) spaceplane. Although the development of reusable, or partially reusable, staged launch vehicles is impressive, the concept of a vehicle that can be launched from a runway and return to that same runway, having delivered a payload to orbit, is the ultimate space launch technology. Perhaps that is why serious engineering concepts have been published on the subject since the early days of the Space Age.

However, it is always easier to publish an engineering concept than to develop actual flight hardware and the list of failed projects is a long one. The 1980s was a particularly rich decade for projects utilising hypersonic engine technology to attain the goal of SSTO: for example, the US National Aerospace Plane (NASP) programme spawned Rockwell’s X-30 and Lockheed Martin’s VentureStar, but they were cancelled due to lack of funds.

Meanwhile, the British Aerospace/Rolls Royce project known as HOTOL (an acronym for Horizontal take-off and Landing) seemed promising, but met the same fate.

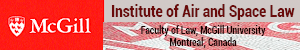

UK Secretary of State for Aviation, Maritime & Security, Mike Kane, (left) with Pradeep Dass, at this year’s Farnborough Air Show where Space Engine Systems was part of the Spaceport Cornwall booth.

UK Secretary of State for Aviation, Maritime & Security, Mike Kane, (left) with Pradeep Dass, at this year’s Farnborough Air Show where Space Engine Systems was part of the Spaceport Cornwall booth.

At least this latter research was continued, from the 1990s onwards, by Reaction Engines with its Skylon vehicle, incorporating the innovative Synergetic Air-Breathing Rocket Engine (SABRE)… but here we are 30 years later with no flight hardware.

Until recently, Skylon seemed to be the last hope for a commercial spaceplane, but this year’s Farnborough International Airshow (FIA) and the Space Symposium in Colorado Springs highlighted a potential competitor (offering a two-stage to orbit solution), in the shape of Canada-based Space Engine Systems (SES).

Hypersonic technology

The intention of SES is to develop a fleet of reusable, horizontal take-off and landing spaceplanes

Put simply, the intention of SES is to develop a fleet of reusable, horizontal take-off and landing spaceplanes that combine the technologies of air-breathing and rocket propulsion during ascent with an ability to return the vehicle to Earth. Of course, this capability is dependent on some fundamental breakthroughs in propulsion technology, which are embodied in the term hypersonics. Essentially, hypersonics is the aerodynamics of travel at more than five times the speed of sound, Mach 5, but it is easy to get sidetracked into the development of hypersonic vehicles per se, which includes military weapon delivery systems. The focus here is using hypersonic technology to realise a two-stage to orbit spaceplane.

Artist’s impression of H1X.

Artist’s impression of H1X.

The DASS GNX is a precooled, air-breathing, turbo-ramjet designed to meet the demands of hypersonic flight and will become the heart of both the HELLO-1 and HELLO-2 flight vehicles.

The DASS GNX is a precooled, air-breathing, turbo-ramjet designed to meet the demands of hypersonic flight and will become the heart of both the HELLO-1 and HELLO-2 flight vehicles.

Indeed, the primary focus of SES is “crafting the lightest, reusable, multi-fuel propulsion system designed to optimise engine performance, with a commitment to pushing the boundaries of space and high-speed flight”, according to the company’s publicity. Its “cutting-edge air-breathing technologies” will form the basis of its proposed vehicles, known as HELLO-1 and HELLO-2.

Speaking to ROOM on the company’s eye-catching FIA stand (shared with Spaceport Cornwall), President & CTO Pradeep Dass said: “The versatility of our spaceplanes is unparalleled, offering capabilities such as point-to-point transportation, suborbital and payload delivery to low Earth orbit (LEO) at an unprecedented low cost per kilogram”.

The HELLO-1 spaceplane is designed as a “one hundred percent reusable” horizontal takeoff and landing spacecraft, using a combination of airbreathing and rocket engines powered by non-toxic propellants. HELLO-1 is designed to fly a suborbital trajectory to an altitude of 100 km at speeds in excess of Mach 5 and, from this altitude, to deploy a transfer vehicle designed to carry payloads to LEO. “HELLO-2 takes this a step further”, said Dass, “with the capability to deliver payloads to the lunar surface.”

At the time of the Airshow, the first test flight had still to be announced, but Dass was optimistic about “the possibility of flight tests by the end of 2024”. If these prove successful, he added, “2025 would become a landmark year”. “We are committed to pushing the boundaries of possibility”, he added, “and next year could be a pivotal moment with HELLO-1 as we pioneer suborbital, point-to-point and low Earth orbit (LEO) missions, which we think will shape the landscape of space exploration”.

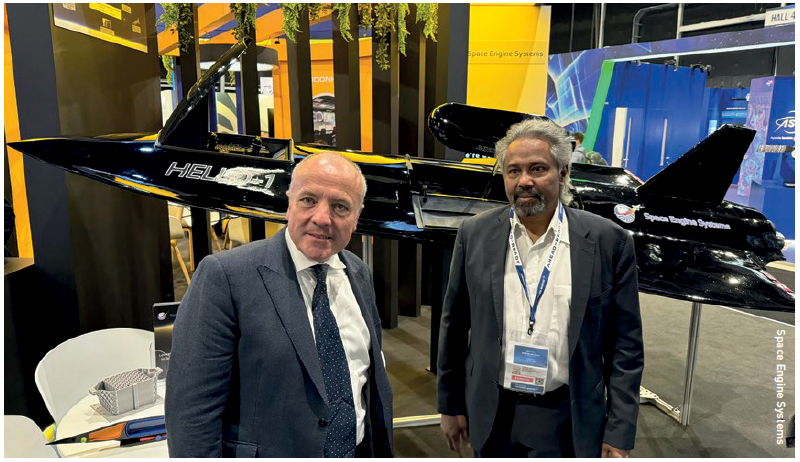

3D printed heat exchanger on display at FIA 2024.

3D printed heat exchanger on display at FIA 2024.

Promise and passion

The intention of Space Engine Systems is to develop a fleet of reusable, horizontal take-off and landing spaceplanes

If the intentions of Space Engine Systems can be achieved, there is no doubt that the capability promises a revolution in spaceflight technology and its applications. Delivering payloads to LEO is, of course, an established business, but it is the delivery of people from A to B that so often excites the media and the entrepreneurial companies that hope to provide the service.

For a start, SES has its ambitions firmly fixed on revolutionising global connectivity with hypersonic travel. The holy grail of hypersonic flight at Mach 5 would reduce transcontinental travel times by eye-watering amounts: for example, the company quotes travel times from Sydney, Australia, to New York, USA, of just 177 minutes, while London, UK, to Edmonton, Canada would be 75 minutes.

However, this is really just the ‘headline promise’ of all proposed crew-rated hypersonic vehicles. More immediately, Space Engine Systems is looking at the potential of its point-to-point technology demonstrator, HELLO-1X, which could transform global organ transplant surgery by facilitating the speedy delivery of organs. According to the company, more than 76 percent of lungs and hearts harvested for transplantation are currently discarded because they cannot reach patients in time for successful transplants. Pradeep Dass was struck by a plea from Dr Jayan Nagendran, a cardiac surgeon and clinician-scientist at the University of Alberta, who emphasised the need to deliver lungs within four hours from anywhere in the world. As a result, SES rapidly incorporated this requirement into its HELLO-1 point-to-point system, to emphasise the goal of saving lives.

In common with many entrepreneurs and developers of space technology, it is clear that Dass is driven not just by the technical practicalities, but also by passion and enthusiasm. “We are driven by a mission to eliminate barriers to hypersonic flight and turn affordable space travel into a reality”, he says. “The company’s fundamental goal is to push the boundaries of sustainable hypersonic flight and space accessibility at the lowest cost possible. But at Space Engine Systems, we are not just pursuing a passion; we are crafting the future of high-speed flight and redefining the boundaries of space accessibility.”

Test cell (top) and graphic depicting test facility.

Test cell (top) and graphic depicting test facility.

Development programme

Essentially, hypersonics is the aerodynamics of travel at more than five times the speed of sound, Mach 5

Between 2021 and 2023, SES accomplished a key milestone by successfully testing its turbo-ramjet using a range of fuels, including hydrogen. The company has also developed the world’s first mobile turbo-ramjet test facility, capable of handling up to 111 kN (25,000 lb force) of thrust.

SES is now constructing the HELLO-1X flight demonstrator, which is designed to reach an altitude of 32 km and speeds up to Mach 5. It is designed to be piloted but can also operate unmanned, offering flexibility for regulatory approval through redundant safety systems.

The HELLO-1 and -2 systems will be powered by the DASS GNX engine, an air-breathing turbo-ramjet with a proprietary cryogenic pre-cooling system; the engine develops a thrust of 88.9 kN and has a specific impulse of 3800 s. According to SES, its heat exchanger solution – built using additive manufacturing techniques [see photo] - is unique and compatible with both high temperatures and cryogenic coolants; it can transfer in excess of 10 MW within 7.5 milliseconds.

The HELLO-1 flight system will be capable of carrying a 550 kg payload to LEO. While the company aims to reach the Moon, it plans first to generate revenue through hypersonic flights for defence, point-to-point travel and LEO missions. The next iteration, HELLO-2, will carry 5500 kg to LEO, 1730 kg to geostationary orbit (GEO) and 760 kg to the lunar surface, and will be followed later by a proposed HELLO-3M, a crewed lunar mission.

Naturally, SES is fully aware of the previously mentioned ‘hypersonics sidetrack’ of weapon delivery systems and believes it is “at the forefront of developing cutting-edge intelligence, surveillance and reconnaissance (ISR) strike capabilities through its innovative hypersonic technology”.

SES’ partnership with Applied Systems Engineering Inc (ASEI) supports the UK Ministry of Defence’s initiative to create a sovereign hypersonic technology base, ensuring rapid response and strategic advantage. According to SES, this collaboration “enhances its ability to deliver advanced propulsion and spaceplane design by integrating ASEI’s expertise in navigation systems and weapon design”.

SES believes that its successful testing of multi-fuel, turbo-ramjet engines, coupled with advanced modelling and simulation technologies, positions the company to address critical defence needs.

“By leveraging these advancements”, it states, “SES is committed to providing ISR strike solutions that offer unprecedented speed and accuracy, capable of velocities up to Mach 7. This capability ensures SES’ readiness to support the defence needs of the UK, Canada and allied nations, highlighting its role as a leader in aerospace innovation”.

A notable advantage of SES is its ability to design and manufacture almost everything in-house. “If it’s not furniture or off-the-shelf computers, we build it ourselves”, says Dass. “The average age of the engineering team is about 35 years, yet they display exceptional dedication and focus on achieving flight. Safety also remains a top priority at SES.”

Pradeep Dass and Ross Hulbert, Spaceport Cornwall business development manager. The spaceport, located in the south west of England, is providing state-of-the-art facilities for Space Engine Systems to test its reusable, horizontal take-off and landing vehicles.

Pradeep Dass and Ross Hulbert, Spaceport Cornwall business development manager. The spaceport, located in the south west of England, is providing state-of-the-art facilities for Space Engine Systems to test its reusable, horizontal take-off and landing vehicles.

Preparing for flight tests

While the company aims to reach the Moon, it plans first to generate revenue through hypersonic flights for defence, point-to-point travel and LEO missions

As with all similar projects, design, manufacturing and ground-based testing leads eventually to flight testing. To continue ground testing and prepare for flight, the company plans to deploy one test system to the US and another to Cornwall, UK, as part of its collaboration with Spaceport Cornwall.

Meanwhile, SES has established a separate entity, Space Engine Systems USA, to obtain approval for use of a supersonic corridor for its planned flight test by 2025.

Dass acknowledged the challenges of securing regulatory approvals but remains confident due to their rigorous AS 9100 quality assurance processes. He says the company has documented every test and failure, learning invaluable lessons from hundreds of ground tests, which boosts confidence in a successful flight.

SES already employs supersonic pilots in the US, who utilise a custom-built simulator with pre-qualified software. The team has integrated parts from known aircraft, including certified ejection seats and landing gear, which should make it easier to navigate the regulatory process, says Dass.

“Our unwavering dedication to advancing high-speed flight and expanding space accessibility propels us into the future. We’re on an exciting journey, conducting ever more advanced engine testing that sets the stage for groundbreaking developments.”

Although there are still many hurdles for SES to leap, Pradeep Dass retains his optimistic stance: “These technological advancements will culminate in the creation of the most cost-effective and efficient transportation system for high-speed flight and payload delivery to orbit”, he boasts. “We will be the lowest cost trucking company to anywhere in space and the Moon”.

The proof of such bold statements lies in the detail of flight tests, technological readiness and regulatory approvals, but if Space Engine Systems is successful, this could be one of the most disruptive technologies seen in the space and aerospace sectors since those SSTO dreams of the 1960s.

About the author

Mark Williamson is an independent Space Technology Consultant and writer, and a Commissioning Editor for ROOM Space Journal. He has 40 years of experience as a satellite communications engineer and consultant to the space industry, space insurance and space education sectors. He is the author of six books, including The Cambridge Dictionary of Space Technology and Space: The Fragile Frontier, has edited three space industry magazines and written more than 600 articles and papers on space technology. He has a BSc in physics and astrophysics from Queen Mary London and a PhD in sustainable development of the space environment, and is a chartered physicist and chartered engineer.