When Joe Anderson first informed ROOM readers of SpaceLogistics’ intentions to pioneer the market for satellite servicing in his article ‘Extending the life of geostationary orbit satellites, (ROOM #21, Autumn 2019), the company’s MEV-1 was just about to launch from Baikonur, in Kazakhstan, in what turned out to be a picture-perfect launch. Here, he provides an update on the mission and a personal view from mission control.

Imagine, for a moment, a scene from a science fiction movie: 36,000 kilometres over the sunlit Pacific Ocean, two satellites glide toward each other through the inky blackness of space. One of these satellites is nearly 20 years old and after a long, productive lifetime beaming television signals to millions of customers, it has run out of fuel and is drifting in orbit. The other, a brand new satellite, is the first of its kind: a servicing spacecraft designed specifically to rendezvous and dock with other satellites.

A room full of engineers, scientists and technicians watch a live feed from the servicer as it slowly approaches the communications satellite, centimetre-by-centimetre, over a period of hours, as they orbit the Earth at more than 11,000 km/hr. Every few seconds, the screens in mission control are updated with new images from one of the servicer’s three imaging systems: visible, infrared, and laser radar (LIDAR). Meanwhile, the servicer’s flight computer builds a model of the relative positions in space, constantly updating it as the servicer creeps ever closer.

Satellite servicing is an economic venture because the largest single cause of satellite retirements is limited propellant capacity

Finally, the servicer is just a metre behind its client. It extends a long probe, which connects with the rocket engine on the aft of the old satellite. The mission controller counts down the distance as the probe is slowly reeled in. When it reaches the designated number, the two spacecraft will be docked firmly together, a long development journey will end and a new five-year satellite servicing mission will commence. At last the call is made – “We have hard dock” – and the room erupts.

There’s just one more thing you need to know about this scene: it’s not from a science fiction movie. It really happened and I was there - on 25 February 2020 - in Mission Control when our servicer, Mission Extension Vehicle-1 (MEV-1), docked with the Intelsat 901 (IS-901) communications satellite, solidifying its place in history and inaugurating a new era of satellite servicing.

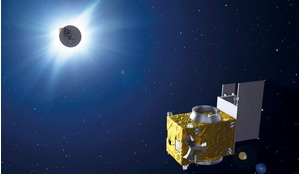

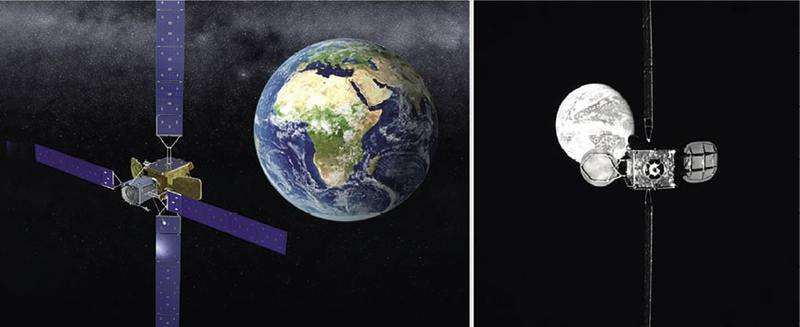

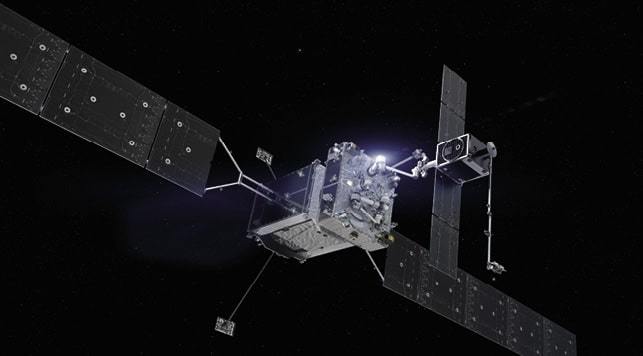

Artist’s impression of MEV-1 docking with its target Intelsat spacecraft.

Artist’s impression of MEV-1 docking with its target Intelsat spacecraft.

Launch of MEV-1 on a Proton rocket from Baikonur Cosmodrome Kazakhstan, on 9 October 2020.

Long journey

While I now work for SpaceLogistics, the subsidiary of Northrop Grumman that built MEV-1, I spent most of my early career at Intelsat, where, ironically, one of the satellites I helped to procure, launch and operate was Intelsat 901. I hadn’t the faintest notion that nearly 20 years after launch I’d be seeing it again - this time through the eyes of another satellite that I had helped to build and put into geostationary orbit (GEO).

As I wrote previously in ROOM, we at SpaceLogistics have been working on MEV-1 for more than 10 years, during which we developed from scratch the technology and procedures required to safely rendezvous, dock with and service GEO communications satellites. We do this by means of a probe mechanism designed to dock with our clients’ Liquid Apogee Engines (LAEs), a rocket used only at the beginning of a GEO satellite’s lifetime to place it in its final orbit. By utilising this near-universal feature, MEV-1 is able to dock with almost 80 percent of GEO satellites, even though not a single one in orbit today was intended to be serviced in space.

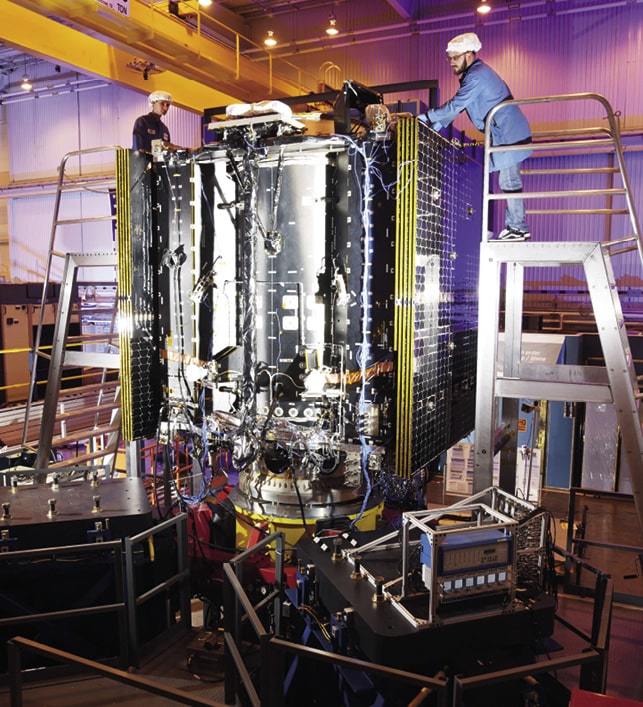

Technicians provide a sense of scale as they work on the first Mission Extension Vehicle.

Technicians provide a sense of scale as they work on the first Mission Extension Vehicle.

Satellite servicing is an economic venture because the largest single cause of satellite retirements is limited propellant capacity. Every year, some 10-20 satellites in otherwise excellent health are shut down because they have run out of station-keeping propellant (required to counteract the gravitational forces of the Sun and Moon that pull GEO satellites away from their designated orbital positions). A single healthy GEO satellite at a prime orbital location (e.g. over heavily populated areas such as Western Europe) can generate tens or even hundreds of millions of dollars per year, making it an economical proposition for operators to extend the lifetime of these satellites with a servicer like the MEV.

Every year, some 10-20 satellites in otherwise excellent health are shut down because they have run out of station-keeping propellant

MEV-1 uses highly efficient Electric Propulsion (EP) engines, utilising xenon propellant to produce far more delta-v (velocity change) than standard chemical propellants. In fact, MEV-1’s EP system has about four times the specific impulse (or ‘efficiency’) of a typical GEO chemical propulsion system. However, the flip side of this high specific impulse is low thrust; the EP system produces only a small fraction of a newton (roughly equivalent to the force imparted on your hand by a few sheets of paper). While not an exact analogy, imagine a car that provides a fuel efficiency of 0.1 litres/100 km, but is limited to a speed of 1 km/h; it can go a long way on a tank of fuel, but it will take a long time to get there!

Similarly, MEV-1 utilises its propellant supply extremely efficiently, but it is slow to travel between orbits due to its low thrust. As a result, it was not until mid-February 2020 that MEV-1 finally arrived in its desired docking orbit close to Intelsat 901.

Artist’s pre-launch concept of MEV-1 docking to Intelsat 901 (left); actual photo of Intelsat 901 in orbit by MEV-1 (right).

Artist’s pre-launch concept of MEV-1 docking to Intelsat 901 (left); actual photo of Intelsat 901 in orbit by MEV-1 (right).

Go for docking

Out of an abundance of caution, we decided to perform MEV-1’s first docking in the geostationary ‘graveyard’, so that - in the unlikely event that anything went wrong with the docking - no other GEO satellites would be harmed. The graveyard is a set of orbits about 300 km above GEO to which satellites are retired at the end of their useful lifetimes to reduce the potential for collisions or interference with other spacecraft in this commercially valuable orbit.

During the docking event, all of MEV-1’s rendezvous and docking activities unfolded exactly as planned. We made a few practice runs where we closed to within a few dozen metres of Intelsat 901 to ensure that all of our sensors and flight computers were operating properly, and also to verify that MEV-1 could make a quick, safe exit from the vicinity of Intelsat 901 in the event of a problem requiring an abort. Indeed, an important part of our development and planning for MEV-1 was the design of a safe trajectory to avoid an accidental contact. The safety and continued health of our client satellites (as well as third party GEO satellites) is our top priority, a factor that gave Intelsat the confidence to entrust their valuable revenue-generating asset to our service in the first place.

Finally, the moment came: early in the morning of 25 February (local time), MEV-1 had closed to within a few metres of IS-901, with all systems operating smoothly. Before this point, no one was entirely sure how Intelsat 901 would look, as there had never been an opportunity to see a communications satellite decades after launch. Would the solar panels have suffered damage? Would the insulation blankets be torn in a way that would interfere with a safe docking?

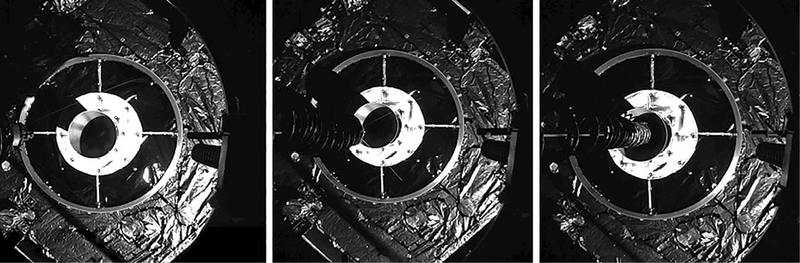

Time-lapse sequence of the MEV-1 probe driving into the Intelsat 901 Liquid Apogee Engine, as photographed by MEV-1 during the actual docking on 25 February 2020.

Time-lapse sequence of the MEV-1 probe driving into the Intelsat 901 Liquid Apogee Engine, as photographed by MEV-1 during the actual docking on 25 February 2020.

Before launch, we had performed a comprehensive verification and validation (V&V) process in order to assess the most likely condition of the client satellite, as well as every possible impact of MEV and IS-901 on each other. For example, when docked, MEV-1 and IS-901 cast shadows on each other’s solar arrays, which is not encountered in standard operations outside of servicing. The imagery from MEV-1 showed that our V&V had been highly accurate, as Intelsat 901 was in exactly the condition we expected, and there were no concerns about pressing forward to a docking.

No one was entirely sure how Intelsat 901 would look, as there had never been an opportunity to see a commu-nications satellite decades after launch

As MEV-1 hovered only about a metre behind Intelsat 901, we gave it the final ‘go’ for docking, allowing it to extend its docking probe to draw the spacecraft together; it is important to note that, while highly automated, all critical commands to MEV-1 remain under human control. In mission control, we saw data indicating that the probe had snagged the LAE exactly as designed and watched as it began to pull MEV-1 tight up against IS-901.

As MEV-1 drove its docking probe through the IS-901 LAE and retracted it, a thrill passed through the control room as the dozens of flight controllers and VIPs realised that the moment had finally come: the journey that had started as a modest sketch on a whiteboard in the mid-2000s had finally resulted in an operating, docked ‘stack’ of spacecraft in GEO. The world’s first satellite servicing vehicle had proven itself in commercial use, opening up a whole new kind of privately funded space market activity.

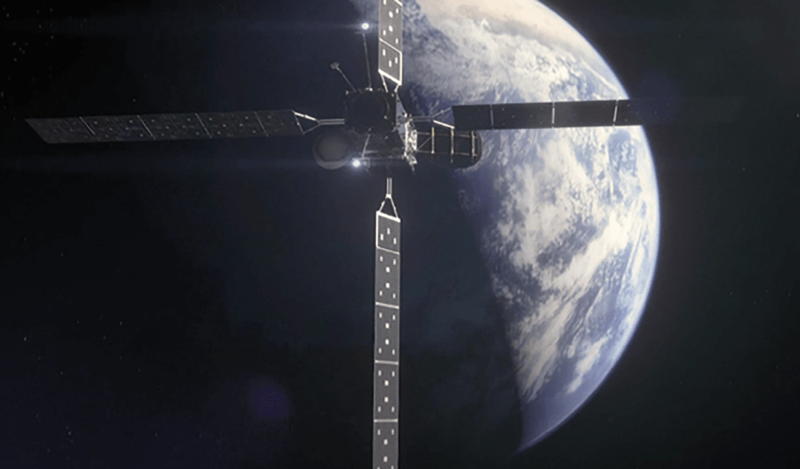

Artist’s concept of MEV-1 using its EP engines (blue glow) between February and April 2020 to tug the MEV-1/IS-901 to its final operational location over the Atlantic.

Artist’s concept of MEV-1 using its EP engines (blue glow) between February and April 2020 to tug the MEV-1/IS-901 to its final operational location over the Atlantic.

Future missions

In the following weeks, MEV-1 tugged the stack slowly to its new operational location over the Atlantic Ocean, using its highly efficient EP engines. Once there in mid-April, like a phoenix rising from the ashes of the graveyard orbit, MEV-1/IS-901 replaced the Intelsat 907 satellite in active service, allowing 907 to be retired. MEV-1/IS-901 are in service today, serving millions of customers across five continents simultaneously and, by the time you read this, will be about one year into a five-year mission.

Following the end of its mission serving IS-901, MEV-1 will depart to serve other clients, as part of its planned mission lifetime of at least 15 years. This could include helping to keep GEO clear of debris by moving satellites that have failed in GEO, prior to retirement, to the graveyard, or helping satellites that are still operating, but lack sufficient fuel, to achieve a graveyard orbit.

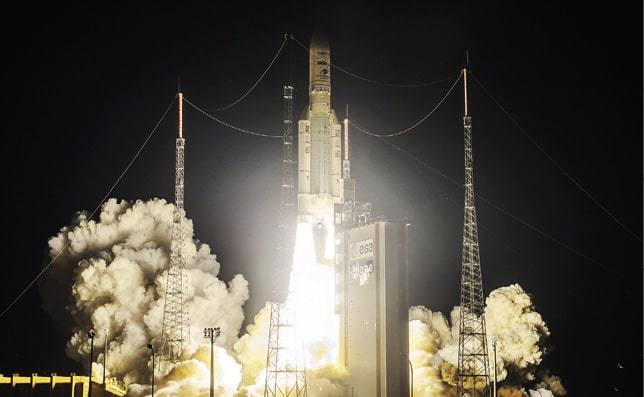

Launch of MEV-2 from French Guiana on 15 August 2020.

Launch of MEV-2 from French Guiana on 15 August 2020.

Excitingly for SpaceLogistics, MEV-1 is only the first is a series of satellite servicing vehicles, with MEV-2 launched in August 2020 to service another Intelsat satellite, which it will reach early in 2021.

Our next spacecraft, in development now for launch in 2024, is the Mission Robotic Vehicle (MRV), an MEV bus carrying a two-armed robotic payload developed by the U.S. Defense Advanced Research Projects Agency (DARPA) under the Robotic Servicing of Geosynchronous Satellites (RSGS) programme. The payload is being flown by SpaceLogistics on a no-exchange-of-funds partnership basis, whereby DARPA funds the payload and SpaceLogistics the MRV and launch. The MRV will carry the RSGS payload and perform a variety of inspections, repairs, tugs and other operations on both commercial and government satellites during its lifetime.

The world’s first satellite servicing vehicle had proven itself in commercial use, opening up a whole new kind of privately funded space market activity

The primary mission of the MRV is to deploy Mission Extension Pods (MEPs), which are small (~350 kg) electrically-propelled vehicles about the size of a two-drawer filing cabinet. These MEPs can provide about six years of life extension to a client satellite, at a lower cost than the MEV alone (in essence, they can be thought of as ‘mini-MEVs’, although the MEV provides other advanced capabilities beyond those of the MEP). To reduce costs, the MEPs lack their own rendezvous and docking sensors, computers and thrusters and will be deployed by the MRV on client satellites.

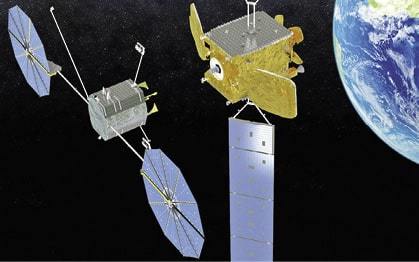

Next generation: the Mission Robotic Vehicle will install a Mission Extension Pod on a client satellite.

Next generation: the Mission Robotic Vehicle will install a Mission Extension Pod on a client satellite.

SpaceLogistics has a variety of other projects in the works, described in the previous ROOM article, which include (among others):

- complex robotic assembly missions to build the space exploration transports and telescopes of the future

- ‘Universal Satellite Bus’ (USB) ports to enable rapid quick-disconnect subsystem upgrades, augmentations and repairs in orbit

- highly efficient space tugs to carry customer payloads all over the cislunar (Earth-Moon) system.

Following the trail that has been blazed by the successful docking of MEV-1, the company sees its overall mission as ‘delivering the future of space’ by enabling, for example, satellite servicing and the in-orbit assembly of new facilities. As with many other aspects of space development, science fiction got there first; but eventually science fiction becomes engineering fact, as SpaceLogistics has proved with MEV-1.

Acknowledgment

The RSGS research was funded, in part, by the Defense Advanced Research Projects Agency (DARPA). The views, opinions and/or findings expressed are those of the author and should not be interpreted as representing the official views or policies of the Department of Defense or the US Government. Approved for Public Release, Distribution Unlimited.

About the author

Joseph Anderson is the Vice President of Operations and Business Development for Space Logistics LLC, a wholly owned subsidiary of Northrop Grumman. He has more than 30 years of satellite engineering, management and leadership experience including seven years with Northrop Grumman and 20 years at Intelsat. In his current role, Mr. Anderson is responsible for managing the technical, operational, licensing and insurance aspects of Space Logistics’ satellite servicing fleet, as well as business development for commercial and government satellite servicing. Mr. Anderson earned an MBA from George Washington University, an MS in Engineering from Stanford University and a BS in Aerospace Engineering from the University of Minnesota.