If getting satellites into space seems too costly, then Rocket Crafters, Inc (RCI) could soon provide the solution by means of a new patented 3D printed fuel technology, that would allow the delivery of small satellites to orbits at possibly half the price of current launch costs.

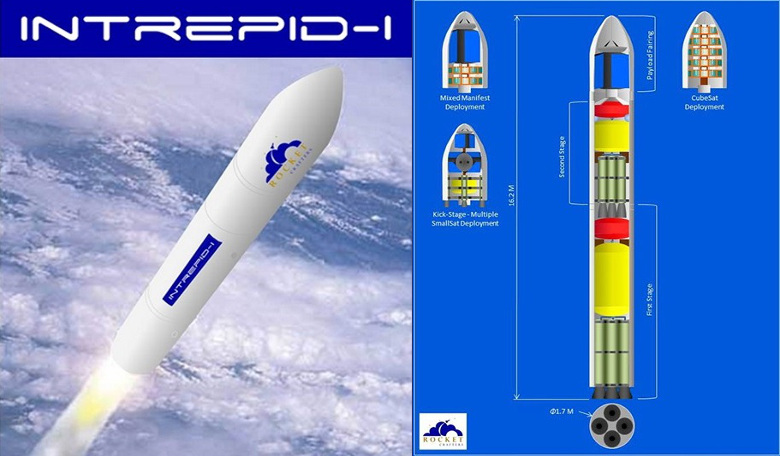

Based in Titusville, Florida, Rocket Crafters, Inc. is a development-stage company that intends to revolutionise access to space and make it available to the rapidly growing small satellite market. In order to achieve this, the company is developing a ‘launch-on-demand’ small satellite launcher known as Intrepid-1™.

In an industry that is seeing companies such as SpaceX reuse rockets to keep costs down, RCI is adopting a different approach by making Intrepid-1, the world’s first mass-producible, expendable launcher.

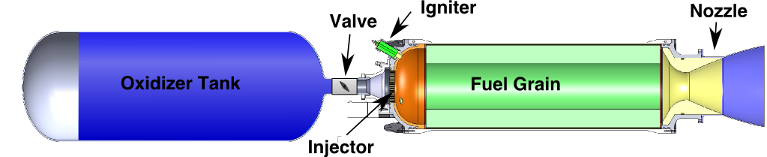

Intrepid-1 is based on a hybrid rocket design. A system that avoids some of the dangers associated with propellant handling in the case of solid fuel rockets and is less complex than liquid rocket engines.

The patent that RCI has been granted takes advantage of 3D printing’s unique ability to precisely fabricate part of the propulsion system known as a fuel grain - a tubular shaped structure that dually serves as the rocket’s solid fuel source and combustion chamber. With the patent in place, RCI will be able to fabricate a launch vehicle with only two moving parts, thus providing a much safer and consistent performing hybrid rocket engine to power orbital launch vehicles into space.

“The fuel grains we are able to produce using this technology provides the structural strength needed to minimize vibration build-up while still enabling the rocket engine to consume high energy solid fuel blends at an accelerated pace,” explained RCI co-founder, President & CTO, Ronald Jones.

A (standard) hybrid rocket propulsion system conceptual overview. Image: wikipedia

A (standard) hybrid rocket propulsion system conceptual overview. Image: wikipedia

Sources of excessive vibration have plagued traditionally designed hybrid rockets for decades and RCI hope that their new patented design rockets will now pave the way for more reliable, and more affordable rockets than ever before.

“I have believed for years that hybrid rockets, due to the inherent safety when propellants are protected against accidental detonation by storing them in different states, could be the solution to make rocket powered flight as safe as airline travel one day. With our 3D printed fuel technology, we now have the means to make this a reality,” said former NASA astronaut and retired Sandia National Labs executive Sid Gutierrez, Chairman and CEO of RCI.

With rocket motors anticipated to be included in orbital launch vehicles by 2019, reality may not be that far away for RCI.