Part of a thruster system made from carbon nanotube material – small hollow tubes with diameters of 0.7 to 50 nanometers – is being tested by NASA to see just how viable the technology is, with the hope that one day it will eventually reduce the mass and improve the performance of its aerospace systems.

The ultra-small tubes, which typically have lengths in the tens of microns, have superior strength but are still extremely lightweight – up to 200 times the strength and five times the elasticity of steel.

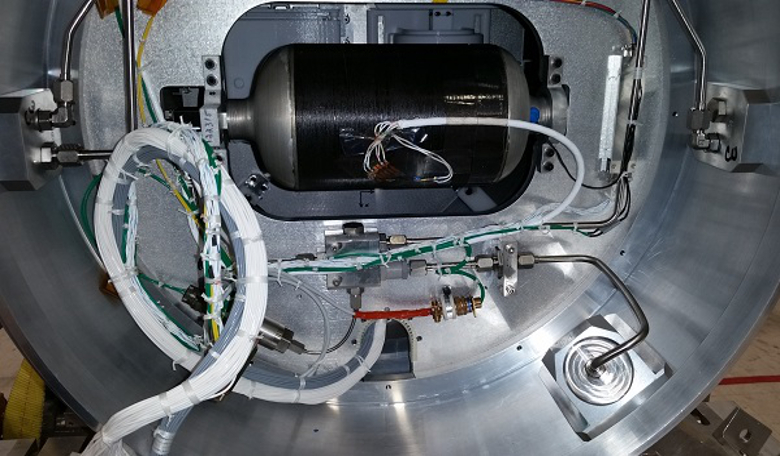

NASA has already performed computer modelling analysis to show that the carbon nanotube composite material could lead to a 30 percent reduction in the total mass of a launch vehicle and have set the ball rolling by creating part of a thruster system known as a Composite Overwrapped Pressure Vessel, or COPV for short.

“No single technology would have that much of an impact to reduce the mass of a launch vehicle by that much,” explains Michael Meador, Program Element Manager for Lightweight Materials and Manufacturing at NASA’s Glenn Research Center in Cleveland, Ohio. “I’m not trying to be cliché, but that is a game changer!”

The tensile properties of the COPV has already been tested as it hitched a ride on a sounding rocket that recently launched from NASA’s Wallops Flight Facility in Virginia.

“We’re going to use the COPV as part of a cold-gas thruster system,” said Meador. “We are one experiment in that payload, but it’s a pioneering flight. This is first time that carbon nanotube-based composites have been flight-tested in a structural component. The COPV flight test will go a long way in showing that these materials are ready for use in future NASA missions.”

The COPV was fabricated with the help of Nanocomp, a company based in New Hampshire. Originally founded in 2004 with only 3 employees, today the company has upscaled tremendously to employ 75 people and overcome the challenges of producing nanotube composite material on a meaningful scale.

As such, the COPV represents the first large item that the company has built. “The NASA-industry relationship was invaluable to scale up the material for space agency use,” said Emilie Siochi, a research materials engineer at NASA’s Langley Research Center in Hampton, Virginia.

“There’s potential for the structural properties of carbon nanotubes to be much stronger than carbon fiber composites, now the state of the art for structural material,” Siochi says. “So if it’s stronger, we’ll be able to build lighter structures needed for access to space.”

There is more work to be done in terms of improving the material’s mechanical properties, however the weight savings, performance, or reduced power consumption that could be achieved with this technology could be hugely beneficial and not just for aerospace applications.

“We’re not looking at magic materials. Rather, we’re finding that when you get down to the nanoscale, there are certain features of materials at that scale that give rise to new properties, new physics that you don’t see above that scale,” Meador concludes. “And that’s what it’s all about. Seeing how you can control and exploit those properties.”