In human spaceflight, the human factor is as important as the technical side. From the very beginning, human spaceflight was made possible not only because of extraordinary scientific breakthroughs, but also because the human spirit was driving the desire to expand the boundaries of knowledge. It is true that the space race became one of the symbols of the Cold War. And yet, it was not simply because of competition between the superpowers that space became an area for human goals and aspirations.

What sort of person becomes a cosmonaut? First of all it is someone who already has a technical specialisation, such as flying, engineering or medicine. It is also someone who has some experience in implementing procedures; carrying out tasks accurately; someone who has the ability to learn continuously; to work in a team situation; to report, to lead and, of equal importance, to follow.

Becoming an astronaut means being ready to learn a lot of new things in fields which you have not yet studied and perhaps never thought you would study. It means constant training, while at the same time carrying out work that involves taking responsible decisions.

How you deal with potential failures is as important as learning about the operation of any space system

One thing that is true of any cosmonaut training centre is that you will learn about how the system was constructed and how it operates now. When a new programme has begun, colleagues will refer to how a similar programme was run in the past, and – crucially – what problems were encountered and how they were solved. This practice of learning from past experience is an integral part of the training. How you deal with potential failures is as important as learning about the operation of any space system.

Sometimes space training becomes literally learning on the job. For example, some instructions you receive in flight are for procedures that you did not practise on the ground. Now you might be asked to carry out a specific robotic task in space. But these situations are manageable because both the crew and the ground staff are trained to communicate in a specific way, sharing knowledge that they obtain together during the preparation for a spaceflight.

Astronaut John Olivas works on the Columbus laboratory module, part of maintenance on the International Space Station during the six-hour, 35-minute space walk

Astronaut John Olivas works on the Columbus laboratory module, part of maintenance on the International Space Station during the six-hour, 35-minute space walk

As a result of this, after the flight, one of the key skill and knowledge transfers for a cosmonaut is to work in Mission Control, becoming a so-called ‘CapCom’ (console operator in the Mission Control centre who is allowed to communicate directly with the crew on board the International Space Station, or ISS). Cosmonauts and astronauts who are not in training also join engineering development teams. Their handson experience cannot be overestimated when it comes to evaluating the man-machine interface for flight equipment.

For the same reason, cosmonauts participate in development and reviews of new in-flight procedures. It can be critically important that a person with personal experience of space operations gives the final recommendations for procedures, as they are testing the new activities on the ground.

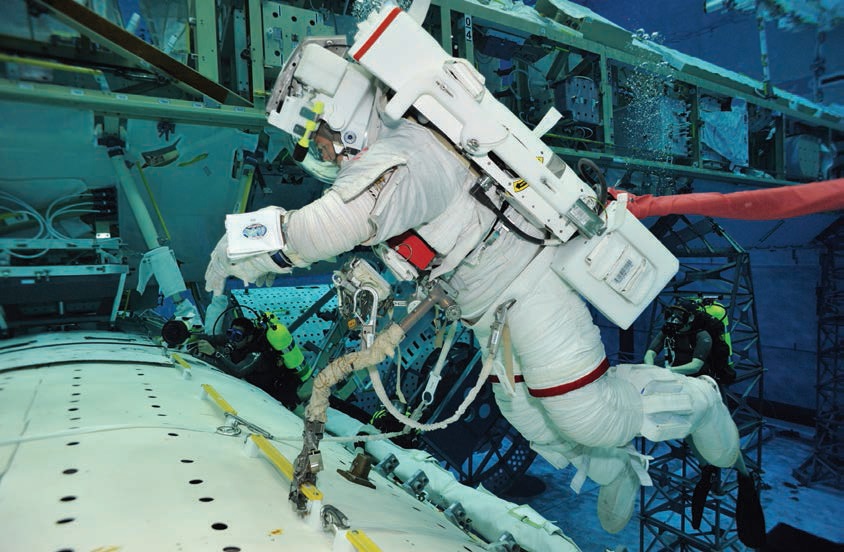

Alexander Gerst, German ESA astronaut, undertakes spacewalk training in the Neutral Buoyancy Lab at NASA’s Sonny Carter Training Facility in preparation for his mission to the International Space Station in 2014

Alexander Gerst, German ESA astronaut, undertakes spacewalk training in the Neutral Buoyancy Lab at NASA’s Sonny Carter Training Facility in preparation for his mission to the International Space Station in 2014

Equally important is knowledge preservation in the broad sense. The space industry has a long lead time. Many items produced for space activities are used only for spaceflight. So a decision about a Soyuz launch that will happen more than two years from now has already been taken, and production of the various components has already started.

Essential continuity

Everything, of course, is carefully documented, and it is this continuity that ensures that the necessary expertise is preserved. But it is also very important to remember that there is part of the overall expertise that can be called intangible knowledge, which is naturally transferred between generations of specialists working in the same domain.

Imagine that that continuity is lost. Despite all the standardisation of procedures and practices, there is no way to record the thinking processes of the individuals who create the various technologies, what obstacles they overcome, which dead-ends they encounter, how they arrive at the conclusion that produces the final product.

Therefore, there is an inherent risk in pausing the production process for a space vehicle once it has begun. Such a pause will mean a reduction of personnel; the shutting down of production lines; and the discontinuation of contracts with supply chains which, in turn, will have to reduce or re-orient their businesses. Not only would it cost a disproportionate amount of money to reinstate such a production line, it would be simply impossible due to the fact that certain components will become obsolete and would no longer be available in the industry. The relevant production lines would be eliminated.

For this reason spare parts for some of the core systems of the ISS, such as DMS-R (Data Management System for the Russian Segment), were produced at the start of the operation: it was clear that in the lifetime of the ISS such computer components would have no application anywhere else, and so would no longer be available. But the main computer of the ISS has to be maintained in good working order for as many years as it continues to fly. In this context, the sharing of on-the-job experience and knowledge transfer between specialists is vitally important. Intangible knowledge and the handover between generations of experts is an integral part of a successful programme.

It is very important that the long-term vision of the spaceflight programme remains solid and uninterrupted, encompassing all aspects of its evolution. This is the best way for society to fulfil mankind’s natural striving to explore Earth and beyond, while sustaining optimal economic efficiency.