To understand how the world of satellites has changed, you have to start in 1998. The first Blackberry, an awkwardly shaped monochome taco, was still a year away but our global obsession with technology was blooming. The tech industry was gearing up for the third generation of Pentium processor and 56k modems were beginning to take the Internet into households around the world.

Meanwhile, in Washington DC, vice-president Al Gore was taking steps to make his vision for a climate monitoring satellite a reality. The satellite, officially called Triana but nicknamed Goresat, was under development to take real time images from L1 (a point where the gravity of Earth and Sun is balanced) in a mission that the vice-president hoped would better depict our planet’s frailty.

Triana actually had roots in something of a small satellite revolution that never was. The SMEX-Lite satellite bus, which is responsible for connecting various components and computers, was designed to be ‘NASA’s Next Generation Small Explorer’ framework for building small low-cost satellites with short missions. Like most technology viewed in retrospect, ‘small’ is relative. Triana weighed about the same as an early model Fiat 500 - much lighter than your typical school bus-sized satellite. For the time, it was light, inexpensive (about 150 million dollars), and had been constructed quickly. Unfortunately, it hadn’t been completed fast enough. By the time it was done, the project had been shelved due to mix of more important missions and political pressure. The satellite itself was carefully tucked away in the hopes that it could someday be launched. While Triana slumbered, wrapped in plastic at a NASA facility, the world was rapidly changing.

Wingo Wong, a Spire engineer, works on satellite assembly at the company’s Glasgow office.

Wingo Wong, a Spire engineer, works on satellite assembly at the company’s Glasgow office.

In 1999, three years before PayPal’s IPO made Elon Musk a multi-millionaire, Jordi Puig-Suari of California Polytechnic State University and Bob Twiggs of Stanford released their vision for the CubeSat reference design. It was a 10 centimetre cube that contained enough electrical components to be on par with Sputnik.

The design, which was based on the size of a shoe box, was initially dismissed by most if not all of the space industry. At best, it was considered a research tool. At worst, it was considered a toy. Time and innovation would eventually change that but it would take many orbits round the Sun before that could happen. In the 17 years since, we saw Moore’s law continue to make processors more powerful, more efficient and smaller. The smartphone put a supercomputer in your pocket, lightweight drones began to take flight, and advances in hobbyist electronics (Arduino, RaspberryPi and sensor technology) became ubiquitous in hobby shops and classrooms around the world. It is those exact same advances that have taken the CubeSat from Sputnik to smartphone.

The amount of innovation seen in technology since the late 1990s has changed the way we work, connect and live. The aerospace industry however, on the whole, has been adapting more slowly. Throughout the 2000s, traditional satellite launches continued to keep the scales tipped in favour of traditional satellites - both in terms of deployments and in raw mass. Yet the CubeSat was quietly surging. Between 2002 and 2010, the number of scholarly mentions in academic papers per year of the term ‘CubeSat’ had quintupled from around 100 to well over 500. When a groundswell of support for launching a new and much needed climate and space weather monitoring satellite revived the debate over Triana in 2011, interest in CubeSats had already garnered the attention of over 3000 academic papers.

The design, based on the size of a shoe box, was initially dismissed by most if not all of the space industry

Over the next few years, two paths would emerge. First, NOAA got the greenlight to refurbish and launch DSCOVR. Despite its new name, the DSCOVR satellite was not new. Taking the Triana satellite out of mothballs was the fastest and most efficient way of getting a new Earth-observation satellite into orbit. The constraints placed on NOAA - time and money - had produced a very inventive solution. Then just the next year, it became impossible to ignore the innovations happening in the world of small satellites as the number of CubeSat deployments surpassed traditional satellite launches.

Constraints, however you look at them, have an interesting effect on creativity. Psychologists, entrepreneurs, artists, and even economists have long discussed and debated how limitations can lead to breakthroughs. Marissa Mayer, of Google and Yahoo fame, once famously wrote an article titled ‘Creativity Loves Constraints’ where she outlined how limits can ‘shape and focus problems and provide clear challenges to overcome’. Prof Twiggs’ 10 cm box provided that spark for creativity at a perfect moment in global technology.

Our ability to get to space and operate there has been getting easier thanks to aerospace standing on the shoulders of consumer technology and other industries. Both SpaceX’s rockets and Spire CubeSats run on Linux - which is the same operating system that underpins Android. The processor in many of those small satellites is nearly identical to the ones that power millions of iPhones and Galaxy phones. At its core, the ‘new space race’, has been powered in part by our insatiable demand for cool gadgets.

The size constraints of CubeSats, which are at most around three litres in volume, challenge engineers to integrate more and better components into each new generation of satellite in the same way Samsung and Apple have to push the limits of technology to design thinner and more powerful phones. In just the short span of two years, the computing potential of a Spire satellite main computer went from about 180 million instructions per second to over two billion. As computing power and efficiency continue to advance, so has the ability of inexpensive satellites to crunch data in real time from the edge of space.

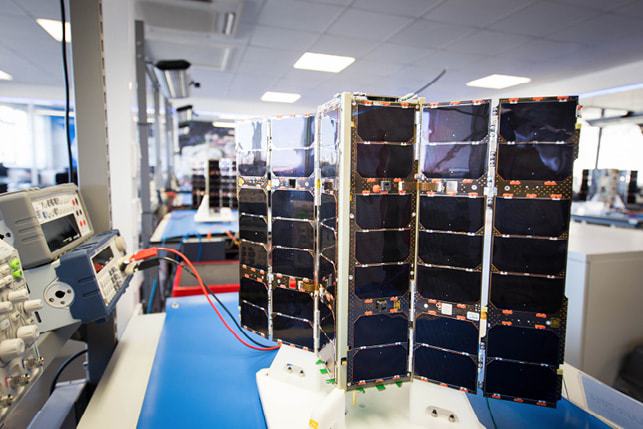

LEMUR-2-TRUTNA, scheduled to be launched this year, has it’s solar panels extended for testing. The panels are folded for launch but extend shortly after deployment into orbit.

LEMUR-2-TRUTNA, scheduled to be launched this year, has it’s solar panels extended for testing. The panels are folded for launch but extend shortly after deployment into orbit.

Many hurdles are still faced by CubeSats. The size severely limits them in key areas. Optics, especially those with high spatial resolution, are incredibly difficult to fit into a small form factor. Many CubeSats include cameras either for novelty or specialty applications rather than as the main focus of the spacecraft. The packaging of a high quality imaging payload is limited by the properties of light, which begins to disperse when passing through a small opening. In order to offset that effect when gaining ‘zoom factor’, you must increase the size of the lens. For a small satellite, that mean it must use as much volume as possible to allow for increased ground resolution. That allows little room to do much else.

On the other hand, the small form factor favours deployables - components that can fold, spring or otherwise ‘deploy’ shortly after entering orbit. Radio frequency based technologies which use antennas for signal intelligence are especially well suited to the constraints of CubeSats. Ship and goods tracking, animal tracking and passive weather data gathering are all poised for incredible improvements. The sheer number of sensors that CubeSats can put into space will produce data points that are available in near real time globally. How we process the ‘noise’ that comes from Earth may become the next big data race.

Constraints, however you look at them, have an interesting effect on creativity

There are still many hurdles that stand in the way of collecting actionable global data in the way we dream of. With each launch, SpaceX gets closer to a truly reusable rocket. There are Instagram pictures and videos, tweets from Elon Musk, and super-slick streaming video coverage with each event. Yet the industry continues to be plagued by constant launch delays. The only safe tactic for a company producing small satellites at scale is to diversify by getting on a wide array of launches. No matter what providers are chosen, launches will be pushed back, moved up, and every once in awhile - explode. Getting something into space turns out to be quite a challenge.

Long before a satellite ever reaches space, it faces some of its biggest opposition. Regulations, many of which many were written long ago during the Cold War, come into play. While commercial satellites (and to that end commercial CubeSats) were recently removed from the International Traffic in Arms Regulations (ITAR) list in the US, any component with military origins (some of which seem completely benign) can still place a satellite into an entirely different category of export control.

When it comes to commercial satellites, EAR (Export Administration Regulations) has replaced ITAR. It adds yet another wrinkle to an already complex regulatory landscape where even foreign produced hardware is regulated if it was designed in the US. These difficult export limitations make it impossible to launch from some countries, difficult to launch from others, and expensive in terms of documentation and legal hours billed.

The only safe tactic for a company producing small satellites at scale is to diversify by getting on a wide array of launches

Regulations obviously have a strong effect on the supply chain. A large number of vendors have sprung up in Europe producing ITAR-free components and CubeSat developers seek to integrate as much non-space-specific componentry as possible. When it comes to nanosatellites, everything from consumer electronics to ‘made for the ground’ ccommercial-off-the-shelf components work exactly the same in space. For CubeSats in Low Earth Orbit (LEO), which is below the Van Allen radiation belts, radiation hardening isn’t a big issue and run of the mill electronics stand to last until the satellites naturally de-orbit.

Spire engineers work on the next batch of LEMUR-2

Spire engineers work on the next batch of LEMUR-2

That leads us to what makes CubeSats so exciting: by using components that have already reached economies of scale, companies can take years and millions of dollars off the development of spacecraft. A new innovation in consumer robotics could be placed in space in less than six months. New smartphone processors can be in space in the exact same amount of time. Every advance that happens in every industry outside of aerospace within the size and power profile of a CubeSat could be in LEO in under six months.

Furthermore, since the spacecraft run open source operating systems, running on-orbit upgrades can be nearly as simple as updating your iPhone. The only time spent waiting on software updates is for the developers to finish writing and testing them. As long as it fits into three litres, it can find itself on a ride into orbit.

Innovation in truly modern aerospace is about putting data collection in orbit in a cost and time efficient manner. That is why when you look at the DSCOVR satellite project, you shouldn’t see an over-budget satellite from the 1990s but instead you should see a remarkable feat of creativity that took a satellite from refurbishment to space in two years. Innovation then, in software or hardware, no longer needs to take place in the aerospace world to end up in space. It can be in an office in Washington DC, an electronics lab in South Korea, or startup in Silicon Valley.