In space, humans are disconnected from Earth and agriculture. Farming in space is still contingent on plants, which require light, water and a medium to grow in, usually soil. Finnish food technology company Solar Foods has created a protein that can be made ‘out of thin air’, which might leap many of the hurdles of producing food beyond our planet.

We are called Earthlings for a reason and it is our dependence on the soil of Earth and farming that has allowed human civilisation to progress to the present level. We cannot be a truly spacefaring species until we can produce the food we need in the vacuum of space.

In order to go further into the solar system, humanity has to find a way to make food on board spacecraft and on inhospitable planets. Presently, humans exploring the hostile frontiers of space need to take their consumables with them, which takes up valuable cargo space. Even the largest space station, the International Space Station, can store only around six months’ worth of food, and there are regular shipments to resupply it in low Earth orbit (LEO).

Once you start increasing the distance from Earth, resupply is not a viable option. The Moon, at a distance of 384,000 km, is a thousand times further away than the ISS but Mars is, on average, 225 million km from Earth. Even at its closest approach, which occurs every two years, Mars is 62 million km from Earth, 160 times more distant than the Moon. Moreover, with our current rocket technology, the journey to Mars would be at minimum a 21-month roundtrip: nine months to get there, three months there waiting for Earth to align and nine months to get back.

Solar Foods produces protein by gas fermentation in a bioreactor – this way of producing protein is 10 times more energy-efficient per hectare than plants and 100 times more climate friendly than livestock.

Solar Foods produces protein by gas fermentation in a bioreactor – this way of producing protein is 10 times more energy-efficient per hectare than plants and 100 times more climate friendly than livestock.

Of course, the mass of the food is also an issue, because for launch purposes every gram counts. Each of the packaged daily meals consumed by an astronaut weighs about 0.83 kg. A Mars-bound crew of four eating three meals a day would require around 6.4 tonnes of food for their trip. This is the minimum amount and it excludes the mass of the water required. Since the expeditions could well be longer, space travellers will have to rely on having the means to grow food and process it en route.

Several plants have already been grown in the zero-g environment of space, with most of the successful ones being leafy greens like lettuce, cress and bok choy. In 2005, the European Space Agency (ESA) produced a list of nine crops it believed could be feasible to grow in greenhouses on Mars: rice, onions, tomatoes, soya, potatoes, lettuce, spinach, wheat and spirulina (a species of microalgae). Of these plants, soybeans and spirulina are the only ones that constitute rich sources of protein and both require a decent amount of water to grow.

Naturally, all plants require a source of light, water and a medium in which to grow, but innovations in hydroponic and aeroponic farming have allowed some plants to be grown without soil, either immersing the plant roots in a nutrient water solution or spraying it as a mist directly on the roots.

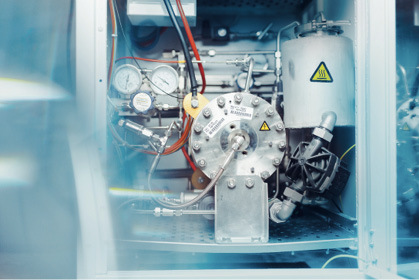

Solein bioreactor

Finnish food technology company Solar Foods has created a protein that can be made ‘out of thin air’

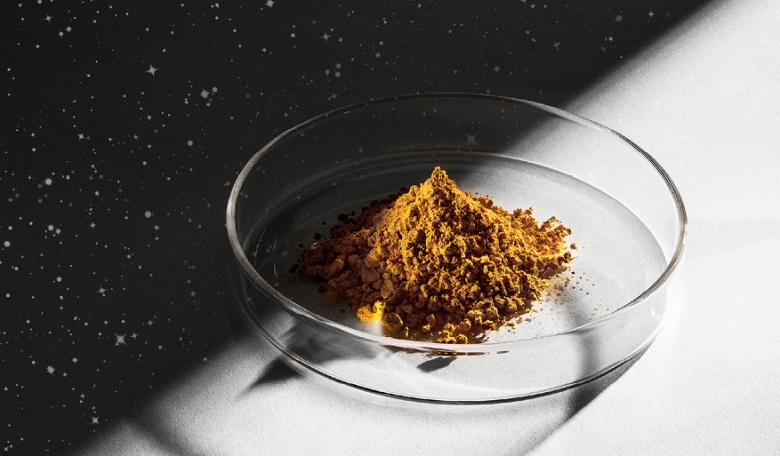

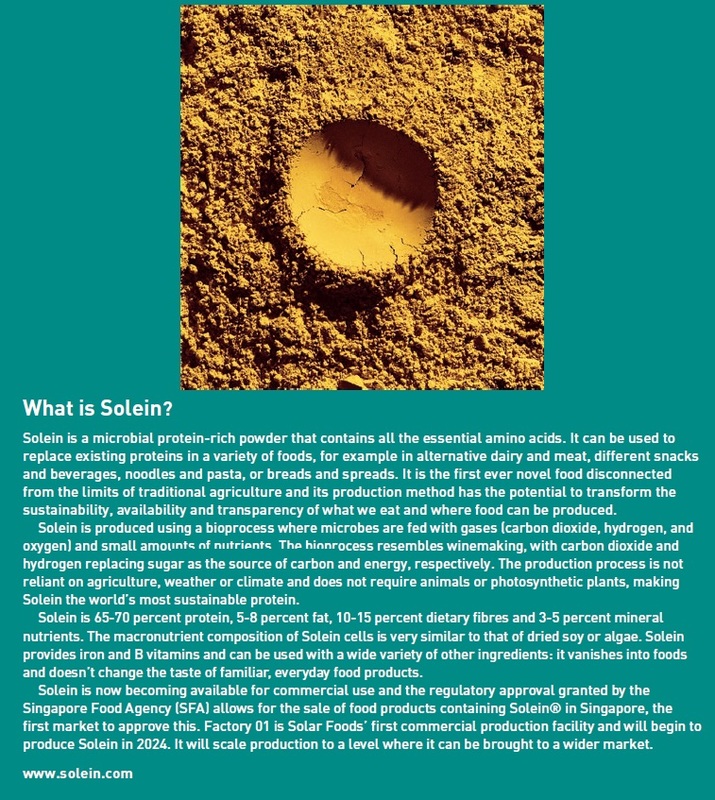

In 2021, NASA and the Canadian Space Agency (CSA) organised the Deep Space Food Challenge, which seeks new space food solutions. Finnish company Solar Foods was one of the first-phase winners with its microbial protein-rich powder called Solein. It is made from single-cell organisms, which only require air, electricity and trace amounts of mineral nutrients to grow in a bioreactor.

Solar Foods has also designed a Solein production unit concept that uses gas fermentation technology and is currently developing and building the first version of a bioreactor that would fit into a space vessel and produce Solein on a space mission. The compact bioreactor is a prime example of how we can scale down and recreate the bioprocess in much tighter confines.

A conceptual design for a space-faring food production system. A 40 litre bioreactor would fulfill the daily protein needs for a crew of four astronauts, while using the resources available onboard the spacecraft – waste gases CO2 and H2. Practically all of the water needed can be recycled.

A conceptual design for a space-faring food production system. A 40 litre bioreactor would fulfill the daily protein needs for a crew of four astronauts, while using the resources available onboard the spacecraft – waste gases CO2 and H2. Practically all of the water needed can be recycled.

When it comes to LEO missions, a solution like this can also save money as fewer rockets are required for resupply missions, thus leaving more resources and budget for other essentials. Arguably, for missions that go beyond the Moon, a spacecraft fitted with a Solein production unit could be the crucial factor that makes the whole journey possible.

Interestingly, the Solein bioprocess uses the byproducts of breathing, as the carbon dioxide emitted by the respiration of the crew can be utilised directly for food production. The microbial cells are fed carbon dioxide, hydrogen, oxygen, nitrogen (which can be sourced from urea) and some minerals. The microorganisms are then able to make amino acids, carbohydrates, lipids (fats) and vitamins.

Solein’s taste has a delicate touch of umami, which blends into any other flavours, so it can taste like anything it is used as an ingredient for.

Solein’s taste has a delicate touch of umami, which blends into any other flavours, so it can taste like anything it is used as an ingredient for.

Even photosynthesis, the method plants use to convert energy into nutrition, is not as efficient as this method and, unlike conventional food production, it takes just a fraction of the water and other resources to produce the same nutritional amounts. When it is time to harvest the Solein, the excess water is removed and the protein-rich Solein concentrate can be formulated into the final food products.

The gas fermentation of Solein is uniquely well suited for food production in space as it taps into underutilised resources that can already be found onboard the spacecraft. Although it requires about 50 kWh of energy to produce 1 kg of Solein, almost all of this energy is spent on splitting water into oxygen and hydrogen via electrolysis. This is still 10 times more efficient when compared to plants and any spacecraft environmental control and life support system (ECLSS) includes an electrolyser for oxygen production.

The hydrogen produced by the electrolyser presently has little use on a spacecraft and is vented into space, but losing hydrogen means that the spacecraft is effectively losing water, which necessitates frequent water resupply. The beauty of Solein production is that we can use up all of the surplus hydrogen produced by the ECLSS, thus retaining it in the loop and saving water. This also means that the excess power needed for Solein production becomes negligible as no additional water splitting is needed to produce hydrogen.

Water and electricity in; hydrogen and oxygen out. Solar Foods operates an electrolyser that splits water into its constituent elements using renewable energy. A similar electrolyser is already flying on board the ISS, and will fly on future missions to the Moon and Mars.

Water and electricity in; hydrogen and oxygen out. Solar Foods operates an electrolyser that splits water into its constituent elements using renewable energy. A similar electrolyser is already flying on board the ISS, and will fly on future missions to the Moon and Mars.

Space food

Solein is made from single-cell organisms, which only require air, electricity and trace amounts of mineral nutrients to grow in a bioreactor

Astronauts’ diets are highly tailored to meet their personal nutritional requirements in a microgravity environment. Based on what we know, Solein’s nutritional contents should support and supplement space meals quite well. Solein consists primarily of protein and contains iron, fibre and B vitamins too. As a result, balanced space meals in the future could well be made up of carbohydrate-rich vegetables farmed in space, complemented by dishes made of protein-rich Solein produced onboard.

However, we yearn for more from food than nutrition alone: food should taste good and have texture and substance. Solein is a very functional ingredient with many uses. In its test kitchen, Solar Foods has created stuffed ravioli, alternative meat-filled bao buns and ice cream out of the various applications of Solein. The taste has been described as “a delicate umami flavour that blends into anything you use it for”.

Research into how one can sustain life on a space vessel also gives us tools to understand how we can get rid of our wasteful resource dependency in agriculture here on Earth. If we can manufacture protein on a spaceship, then there’s no reason why we cannot do it anywhere on Earth: in scorching deserts, in freezing Arctic regions, or in the middle of a paved industrial area with no fertile land or farm animal in sight.

We are excited to see if Solein can help humanity reach Mars. However, we also remain committed to solving the issue of food here on Earth. The challenge of space food is a great pressure test: can you make food in environments where it is supposed to be virtually impossible? Solar Foods’ answer to that is yes.

Solar Foods’ Solein bioprocess is the culmination of years of cutting-edge research. Solar Foods is actively performing R&D to introduce new properties to Solein, or altogether new products.

Solar Foods’ Solein bioprocess is the culmination of years of cutting-edge research. Solar Foods is actively performing R&D to introduce new properties to Solein, or altogether new products.

Sustainability

A self-sustaining closed-loop system of food production would be sustainable in the truest meaning of the word. Food systems on Earth are built on exploited animals, fertilisers dependent on fossil fuels and farmland that could be reforested. Planning for the hostile environment of space does away with all of that immediately and allows us to design more resilient food systems for Spaceship Earth too.

Our Earth is a finite rock travelling across the cosmos, a space of limited resources. If humanity is to persevere and become more than we are today, we need both to learn to live in harmony with nature here on Earth, and to grow our reach beyond our planet. Making a decentralised food system possible on Earth and giving astronauts a tool that can carry them further than Earthlings have ever travelled is the work of today - and of tomorrow.

Solein is a new crop to harvest for humankind and can arguably be compared to the discovery of the potato. We are introducing an entirely new ingredient to the world of food and it’s a watershed moment for how we think of what we eat.

About the author

Arttu Luukanen is the Senior Vice President, Space & Defence at Solar Foods. Prior to joining Solar Foods, Arttu was the CEO of a Finnish growth company Asqella Oy which, like Solar Foods, was spun out from the VTT Technical Research Centre of Finland. At VTT he was the Research Professor of Micro & Nanosystems and the director of MilliLab - the Millimetre-wave Laboratory of Finland. Arttu holds a PhD in Applied Physics and is an elected Fellow of the Finnish Academy of Technology. His hobbies include sports, amateur astrophotography and Telemark skiing.