Infrastructure is the next big thing in space. Today we launch, on average, near 15 times more satellites than we did during the past decade and around the Earth, the Moon and beyond, we see new types of space systems, such as satellite constellations, emerging. Meanwhile, to support the sustainable development of our civilisation, numerous challenges need to be addressed from space: monitoring our impact, increasing our connectivity, exploring the solar system… such applications require the implementation of large space facilities. As result, space will become increasingly crowded and complex, and an efficient logistics system is essential to ensure the sustainability of this new economy.

From the beginning, the foundation of our civilisation has relied on our capability to provide logistics - the movement and management of materials. Throughout history, we have developed our capability to transport goods and people by land, water and air using more and more sophisticated and organised networks. Lately, we have extended our reach to space, but so far with limited capability of movement between orbits, satellites are effectively ‘trapped’ for the whole of their lifetime.

As we can already see in our day-to-day life on Earth, the performance of any infrastructure is nothing if not supported by organised logistics services. With the upcoming in-space infrastructure we need to understand the keys to an appropriate end-to-end mobility service. Furthermore, it is important that we anticipate the benefit we can expect from this new type of logistics and think ahead to future space systems to increase the reach of space applications even further.

As the first cornerstones of this new space industry era, commercial constellations are being deployed at an unprecedented rate by both start-ups and legacy actors: OneWeb, Starlink or Telesat for broadband; Kineis, Astrocast or Myriota for Internet of things (IoT); and Planet, Iceye or Capella for Earth observation.

We can already see that the lack of mobility acts as a serious brake on both the overall cost and the performance of these constellations. From launch to operations, different types of mobility are required for the satellites. The obvious one is access to space, which requires powerful rockets to escape from Earth’s gravity, but, after being released, the spacecraft will need to reach its operational orbit, maintain it and retire from it at the end of its lifetime.

Each operation requires different performance in terms of lifetime, delta-V capability and reliability. They must be well understood to find the approach that supports the space system intended by the operator. This is even more important at constellation scale as orbit positioning is a key factor for the overall performance.

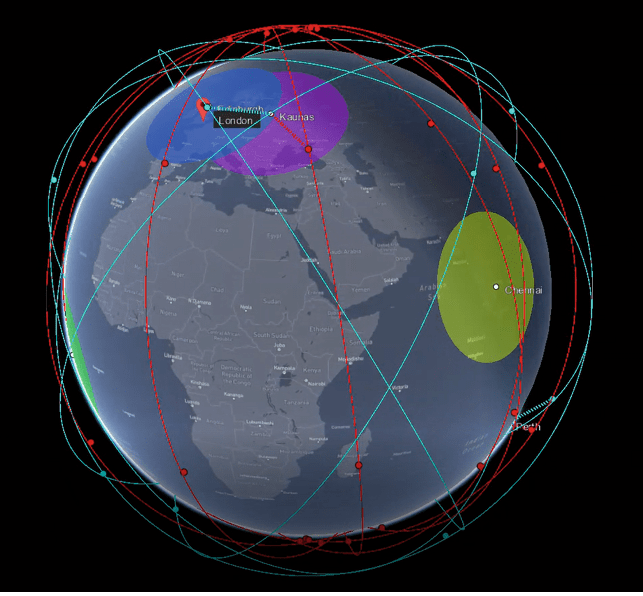

Following the service need of revisit time, data delay or area of coverage, the geometry of the constellation can take different shapes. This geometry also needs to take account of logistics problematics, such as launch solution and ground stations.

Following the service need of revisit time, data delay or area of coverage, the geometry of the constellation can take different shapes. This geometry also needs to take account of logistics problematics, such as launch solution and ground stations.

Space logistics problems

With limited capability of movement between orbits, satellites are effectively ‘trapped’ for the whole of their lifetime

Space logistics is not an end-goal for operators, as it does not provide added value to a targeted service, but it is a necessary way to deploy a service and the key is to optimise it. By enlarging the field of possibilities, space logistics can provide substantial gains in flexibility during the whole spacecraft lifetime from design to decommissioning. Today, several options to move an object in space are available and more options will appear during this decade.

Considering that each constellation is unique in its structure, in the service it provides and in the associated business model, each operator may have a personalised set of problems. As a result, we need to focus on the specific problems of space logistics for each operator.

Finding a solution that takes into account most of the constraints is key for logistics. The choices when designing a satellite or selecting the launch strategy are wide and help operators to gain flexibility in decisions without penalty to the whole system. Eventually, focusing on the logistics problem may open new paradigms for conceiving constellations.

Many, if not all, of these constellations require precise positioning to provide the service they are designed for. Such geometries are the key to enable enhanced performance by maximising service coverage and reducing signal latency. In theory, a perfect design for a constellation can produce attractive performance, but practically the cost of reaching these positions may become quickly prohibitive.

Some are lucky (or wealthy enough) that each plane of their constellation can fill the fairing of single large rocket, but most of the time disruptive constellations are based on small spacecraft platforms. For these platforms, operators have a choice between a rideshare opportunity or taking a ride on a dedicated nano-launcher.

The first choice is affordable, as the price is shared by multiple passengers, but it means accepting a limited choice in destinations that makes shaping the constellation geometry very difficult, or even impossible. For the latter choice, it becomes possible to adapt each launch to a plane of the constellation, but this option is about an order of magnitude more expensive.

However, the concept of in-space mobility allows operators to launch multiple planes with a single launch and then move the satellites to their final orbits. Operators can make the choice to either implement the propulsion capability on their spacecraft to perform this manoeuvre, or they can use a dedicated service by ‘externalising’ the propulsion to another space vehicle.

Dependent on the size of the constellation and the distance between each plane, the delta-V cost for this manoeuvre may be more or less important. For example, spreading satellites over different local times in sun-synchronous orbit may require several hundred m/s of delta-V. In-addition, the manoeuvre requirement is also extremely variable following rideshare opportunities and some satellites may end up with extra propellant representing several decades of in-orbit maintenance.

Ultimately, the choices may impact the design of a spacecraft that is intended to be simplified and standardised as much as possible. Using a dedicated vehicle allows the operator to focus their spacecraft more on the mission. It can also provide more efficient propulsion that enables spacecraft to reach their operational orbit faster and thus generate more revenue.

Spacecraft operations management

Space logistics is not an end-goal for operators, as it does not provide added value to a targeted service, but it is a necessary way to deploy a service and a key to optimise it

Space mobility is not only a matter of hardware, but also applies to software solutions. With a more and more populated and complex space environment, managing constellation geometries can present a real challenge with regard to space traffic. Due to natural disturbances, such as solar and lunar gravity perturbations, satellites are expected to regularly correct their orbits.

Also, as the population of space objects is increasing rapidly, satellites need to perform manoeuvres more often to prevent any risk of collision. These operations require constant monitoring and a good anticipation of the space environment. This monitoring and the scale of the corrective manoeuvres have a direct impact on spacecraft lifetime, because manoeuvres require propellant.

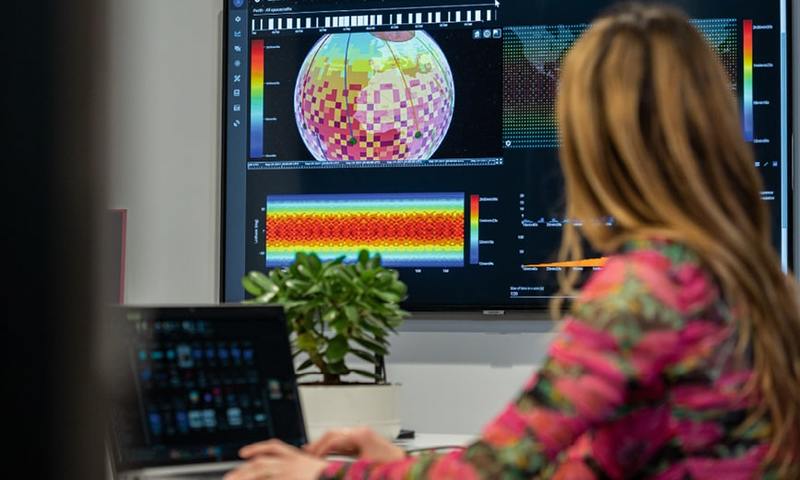

Thus, at constellation level, all these manoeuvres need to be monitored closely from the ground. Automated solutions are necessary on the ground to reduce the workload of the operators in coordinating a full constellation. By monitoring the spacecraft and their orbits, automated manoeuvres are used to simplify the orbit maintenance and the collision avoidance of a full fleet. Such a tool is a key to ensuring the overall performance of the system while reducing the cost of operations and guaranteeing an optimised lifetime.

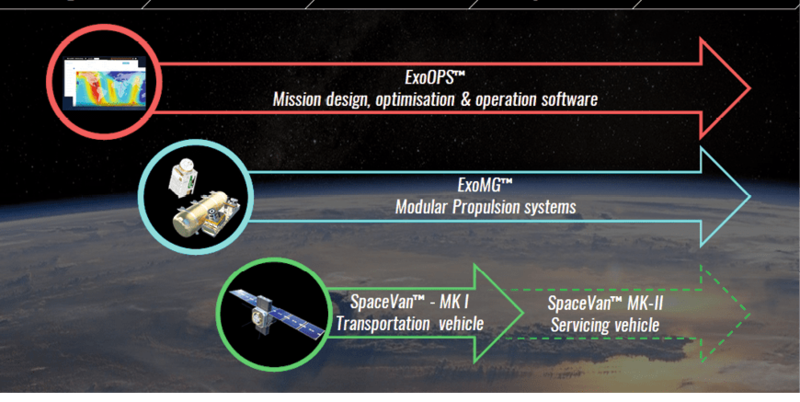

Space logisticians at Exotrail are working on providing a comprehensive set of tailored solutions to offer customers. Exotrail is developing products to meet a variety of needs: electric thrusters with ExoMG™, transfer and maintenance vehicles with the SpaceVan™, mission design software and operational software with ExoOPS™. The common denominator for all these products is that they are part of the global solutions required by operators to solve mobility challenge.

Space logisticians at Exotrail are working on providing a comprehensive set of tailored solutions to offer customers. Exotrail is developing products to meet a variety of needs: electric thrusters with ExoMG™, transfer and maintenance vehicles with the SpaceVan™, mission design software and operational software with ExoOPS™. The common denominator for all these products is that they are part of the global solutions required by operators to solve mobility challenge.

End-of-life orbit disposal

In the bigger picture, a lack of in-orbit mobility may constitute a real threat for space sustainability and thus for mankind. If a satellite’s service life ends, either in an expected or unexpected way, it is necessary to be able to retire it from its operational orbit.

At this stage, several risks are identified that may prevent a proper disposal manoeuvre (e.g. dead satellite, low level of propellant, limited capability to orient the thrust, etc). In the first instance, such a satellite becomes a direct threat to the satellites of the same constellation that are located in the same orbital plane. The consequence is that these satellites will need to significantly increase the number of manoeuvres to avoid the problem satellite.

On a larger scale, this new space debris also threatens the rest of the space ecosystem in that it may trigger the Kessler syndrome, whereby a single debris collision may generate even more pieces of debris.

Handling satellites once they are decommissioned is nowadays a very open question with a lot of possible answers. A dedicated service for that seems to make sense, since operators are naturally willing to use their satellite until the last drop of propellant.

However, challenges are numerous and complex as it requires the capability to dock with a satellite that may no longer be ‘cooperative’. Together with this question comes that of replacing the decommissioned satellite with a new one to keep the constellation working at nominal performance. In this case, an in-space mobility service could be a key for providing delivery of a single satellite to replenish the constellation.

ExoMG™, and its nano, micro and cluster product configurations, is an electric propulsion system for satellites ranging from 10 to 300 kg. The Exotrail ExoMG™ - Cluster2 is a system configuration baselined on three different microsat platforms for both LEO and cislunar missions architecture.

ExoMG™, and its nano, micro and cluster product configurations, is an electric propulsion system for satellites ranging from 10 to 300 kg. The Exotrail ExoMG™ - Cluster2 is a system configuration baselined on three different microsat platforms for both LEO and cislunar missions architecture.

Hitting the road of space mobility

It is never too late to embrace the problems of space mobility and it is always worth considering, at any stage of a project, how an infrastructure can be optimised with space logistics. This is especially true when several new options that may substantially reduce the cost of deployment and operations for a full fleet become available.

Today, space logistics consists mainly of choosing between internal propulsion or external propulsion for delta-V positioning following a rideshare launch. But this choice is becoming more and more elaborate as new types of vehicles are arising from different locations of the space industry.

The evolution of logistics will enable the emergence a new space industry

Some of these vehicles are more powerful and capable of performing transfer between several orbital planes in a very short duration, which will allow payloads to generate revenue more quickly. The next generation of these vehicles will include reusability, whereby the cost of the manoeuvre will mainly depend on the propellant cost in orbit. It will significantly reduce the cost of mobility in orbit but, by acquiring the capability to dock and refill, these vehicles will be able to provide a new range of applications, broadly known as in-orbit servicing.

Advanced software tools are helping us to weigh the pros and the cons for each mobility solution. By considering the time to market and the maturity of the solutions, the operators can get a clear overview of the benefit on their system up to spacecraft design level. As a result, constellations will become more sustainable economically and environmentally. Exotrail is working on a full range of mobility solutions capable of addressing each logistics problem individually.

Virtuous circle of space logistics

As the space economy is expected to be worth more than a trillion dollars by the end of this decade, we can wonder how the needs of space logistics will evolve.

The next generation of these vehicles will include reusability to reduce the expandable cost of mobility in orbit based only on the cost of propellant. By acquiring the capability to dock and refill, these vehicles will be able to provide a new range of applications as part of in-orbit servicing. Refueling vehicles will also require propellant depots in orbit with their own infrastructure and logistics.

The evolution of the logistics will enable the emergence of a new space industry, not only limited to mobility for satellite but extended to in-space freight transportation. Raw materials or semi-finished products can be transported to a space facility for transformation and then moved to another orbit for operations. With developed space mobility we can also envision catching satellites to extend their lifetime, or moving it as a second hand one to a new orbit more adapted for the new owner. This evolution of mobility will allow rideshare and micro launcher capabilities to be maximised, so that cutting launch prices and offering operators last-minute tickets to orbit will matter less.

Eventually, this new space infrastructure will improve the offer from the end-to-end mobility services, with components even manufactured directly in orbit. Larger and lighter solar arrays, for example, could easily be assembled in space to develop faster electric vehicles. From there, we can foresee that in-space mobility will become affordable to reach places like the Moon, Mars, and the rest of the solar system, enabling even larger economies of scale which would benefit from in-space resources. Space end-to-end mobility is now in its early stage but, as infrastructure is key to developing a sustainable economy, a promising future lies ahead.

ExoOPS™ is an intuitive space logistics software developed for mission design and spacecraft operations. This software has been developed following an agile method to provide and operate optimised constellation geometry.

ExoOPS™ is an intuitive space logistics software developed for mission design and spacecraft operations. This software has been developed following an agile method to provide and operate optimised constellation geometry.

About the authors

Paul Lascombes holds an engineering degree from Ecole polytechnique and an aerospace engineering degree from ISAE-Supaero in Toulouse. He started Exotrail during his studies at Polytechnique. Paul is an aerospace enthusiast and a licensed pilot. He has a strong aerospace experience that he acquired during various internships at Caltech (California), Swiss Space Systems and more recently at Airbus Defence & Space in the Advanced Systems team. Paul has the role of Head of In Orbit Servicing and R&D director at Exotrail. He is specifically responsible of all in orbit servicing aspects of Exotrail.

Adrien Palun is responsible for the technical development of the different components of this program including notably the SpaceVan™, the in-orbit transportation vehicle developed by Exotrail. He has 10 years’ experience in small satellites field acquired from European industry and the French space sgency. He is an experienced systems engineer who has been involved in several international projects and directly implicated in different parts of space projects such as AIT, management, and sales. Adrien is enthusiastic about space and everything that is directly connected through space exploration and international collaboration on this topic.